In semiconductor testing, probe cards connect wafers to testing equipment to analyze IC electrical performance. They connect directly to the wafer for important parametric and functional testing. It identifies faults and verifies that each IC satisfies requirements before manufacture. Newer probe card technologies enable minuscule measurements and affect semiconductor yield and reliability as ICs get denser and more refined.

Meanwhile, this article elaborates on probe cards, their types, applications, and benefits.

What is a Probe Card?

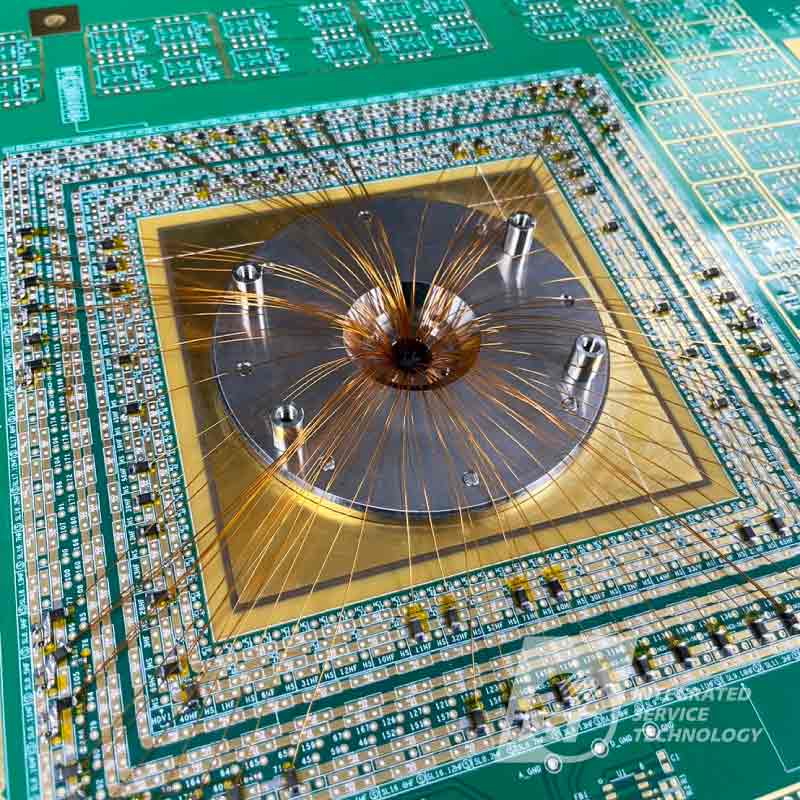

Probe cards link automatic test equipment (ATE) to semiconductor wafers with aligned microscopic probes to touch individual die pads. It enables high-fidelity electrical testing of integrated circuits before dicing and packing. MEMS-based probes and vertical probing designs allow contemporary probe cards to attain micro-level contact pitches and high test frequencies. It minimizes signal loss and measures important parameters.

Such probe cards must be accurate and reliable for simultaneous multi-site testing and lower contact resistance variability for efficient IC testing. Consequently, it lessens retesting and downstream failures in high-volume manufacturing environments.

Key Components of a Probe Card

- Needles/Pins: Needles or pins in a probe card interface with the semiconductor wafer’s metal pads or bumps. They must penetrate oxide layers for a low-resistance electrical path. Precision in placement and force is key. Variations can cause improper contact measurements or damage to the gentle die structure on wafer. Today’s die are so small that probe needles probing area might range from 15um x 30um to 40um x 40um .

- Printed Circuit Board (PCB): The PCB in a probe card is the intermediary that routes electrical signals from needles to the ATE. It’s packed with fine traces that must keep signal integrity at high frequencies. The design may include controlled impedance paths for lower distortion and crosstalk between adjacent signals.

- Interposer: The interposer is an integral part of the probe card utilized between the probe head and the PCB, which a wide variety of space transformation options including WST(Wired Space Transformer), MLC(Multi-Layer Ceramic) and MLO(Multi-Layer Organic). The role of the ST is to fan out the probe points from a small pitch to a large pitch, should be ensured electrical current flow and withstand probes contact stress as well.

- Components: Apply for resistors and capacitors on the signal pathways and control impedance for signal fidelity on the load board. On the other hand, SI(Signal integrity) and PI(Power integrity) simulation will ensure clean signals transmitted to DUT and minimize effects through thoughtful electronics design.

- Support Structure(Stiffener): The support structure of a probe card is a frame or a substrate, so the needles and PCB maintain their alignment. It absorbs mechanical stresses during testing and provides rigidity to avert any movement. Materials must be thermally stable and resist deformation under testing conditions.

Types of Probe Cards

Cantilever Probe Cards

Cantilever probe cards are used in semiconductor testing for low-to-medium pin counts. They probe large pads and older process nodes with cantilever-angled needles. In power devices and analog testing, cantilever probe cards handle greater currents well. Nevertheless, the extended probe length might cause signal integrity concerns at high frequencies owing to higher inductance and resistance. They may leave larger scrub marks on the wafer surface, which may compromise yield in sensitive applications. The advantage is low cost and short lead time.

Vertical Probe Cards

Vertical probe cards suit high-density microprocessor and logic device testing. The vertical needles lower parasitic inductance and capacitance while limiting the probe tips’ distance from the substrate. It retains signal integrity at high frequencies to test wafers with fine-pitch pads. Modern semiconductor nodes need vertical probe cards for accuracy and density. Multi-die testing is possible vertically for better manufacturing throughput.

MEMS (Micro-Electro-Mechanical Systems) Probe Cards

MEMS probe cards use microfabricated structures for accuracy and downsizing to test complicated and tightly packed ICs. Current 3D ICs and logic circuits need single-touchdown testing with precise pitch, and such cards can do that. Parametric testing is more accurate with MEMS probes thanks to their lower contact resistance, high frequency bandwidth and better planarity. Furthermore, they support high-temperature testing for automotive, RF, Memory and industrial semiconductor applications. Customizing MEMS probes for unique applications boosts their adaptability in contemporary semiconductor testing.

Applications of Probe Cards

Wafer Testing

Probe cards electrically touch semiconductor wafer die pads for wafer testing. Each die may be tested before dicing and packaging. The cards can test micro-scale current leakage, threshold voltages, and signal integrity while sending accurate electrical impulses via probe needles. E.g., upgraded logic IC probe cards must handle high-frequency signals with low crosstalk to find small timing errors before processing.

Platform

- Advantest: EXA, V93K, T2000, ND1~4

- Teradyne: Ultraflex+, Ultraflex, J750, ETS

- Cohu: Diamondx, D10, ASL

- NI: STS

- Chroma: 3360, 3350, 3380, 3680

- KYEC: E320, I6000, I2K

- YTEC: S50, S100, S300

Recent Innovations in Probe Card Designs

- New materials for probe tips (e.g., tungsten, diamond-like carbon coatings).

- Spring-loaded probe designs.

- Multi-layered contact structures.

- Adaptive contact force mechanisms.

- Better planarity control techniques.

- High-density interconnect designs.

- Integration of in-situ cleaning mechanisms.

- Self-aligning probe tips.

- Laser-based alignment and positioning systems.

- Embedded sensors for real-time monitoring.

- Low-impedance probe materials.

- Thermal management improvements.

- Better probe tip geometries for contact area control.