With ISO 26262, safety diagnosis mechanism can be added in product development stage of automotive electronics industry, which not only can meet the car makers’ functional safety requirements but maintain corporate reputation based on the safety cycle concept of ISO 26262: from sample, test production, production approval, through to mass production, safe operation, and disposal.

Adapted from IEC 61508 and unveiled in 2011, the ISO 26262 Road Vehicles – Functional Safety Standard is the world first functional safety standard designed for car electronics. Differing from the first edition's limited to passenger cars weighing 3.52 tons or less, the second edition released in 2018 is now applicable to the functional safety requirements of car electronic equipment, assemblies, and components employed by trucks, buses, coaches, and scooters.

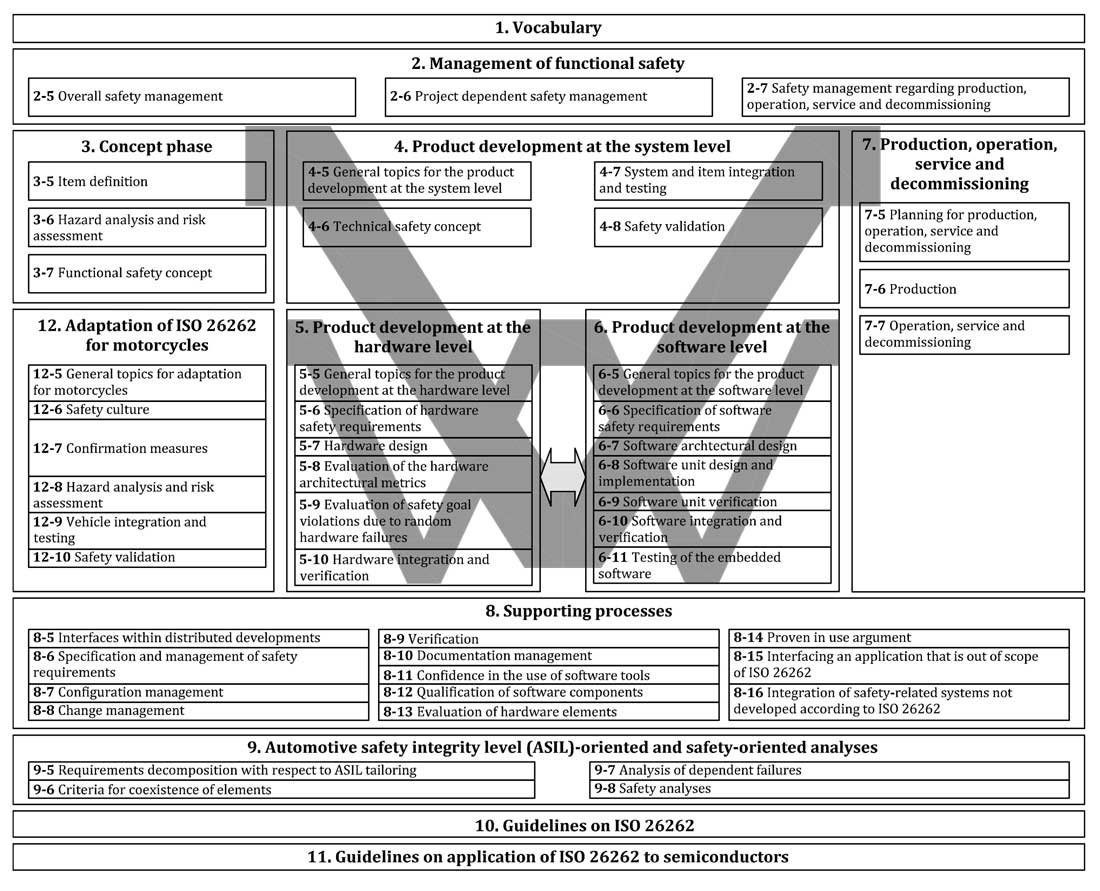

ISO 26262:2018 standard is composed of 12 paragraphs. The V-model for the development process contains a concept phase (Part 3), product development at the system level (Part 4), product development at the hardware level (Part 5), product development at the software level (Part 6), and production and operation phase (Part 7). Paragraph 1~10 of the standard covers the entire life cycle of car electronics and integrates an initial safety concept, functional safety grade assessment, system development, through to production and sales and final disposal with HARA hazards analysis. The last two paragraphs, 11 and 12, designed for semiconductor application guidelines and scooter application.

ISO 26262: 2018 is composed of 12 paragraphs

The Superiority of iST

- Semiconductor chip peripherals (design, manufacturing)

- Automotive electronics component

- Automotive electronics module

- Automotive electronics system product

- Safety related software

- Semiconductor industry

- LED industry

- Photoelectric industry

- MEMS industry

- Other automotive electronics peripheral industry

Contact Window | Miss. Chen/Grace | Tel:+886-3-5799909#8916 | Email:web_isd@istgroup.com