Thick Ag Process

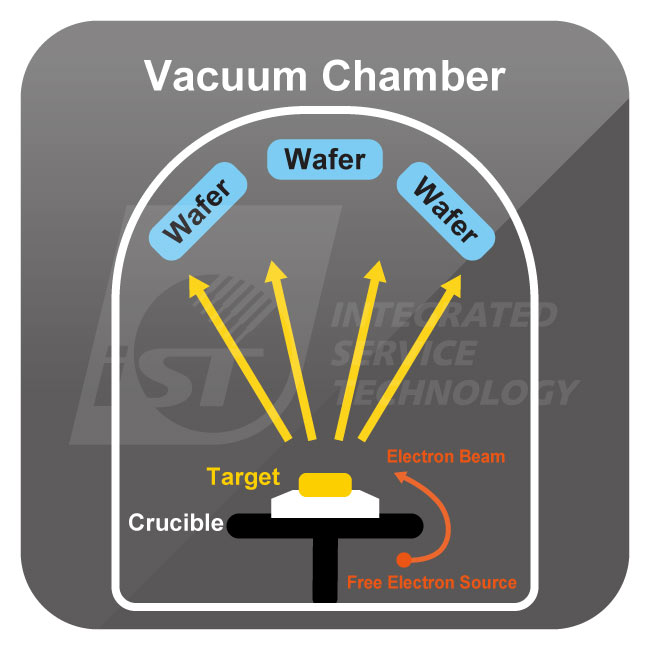

Feed wafers into evaporator after successful IQC (Incoming Quality Control) with slugs in compliance with types and thicknesses given by the customer; perform Metal Evaporation Deposition and thickness measurement before OQC(Outgoing Quality Control).

The Superiority of iST

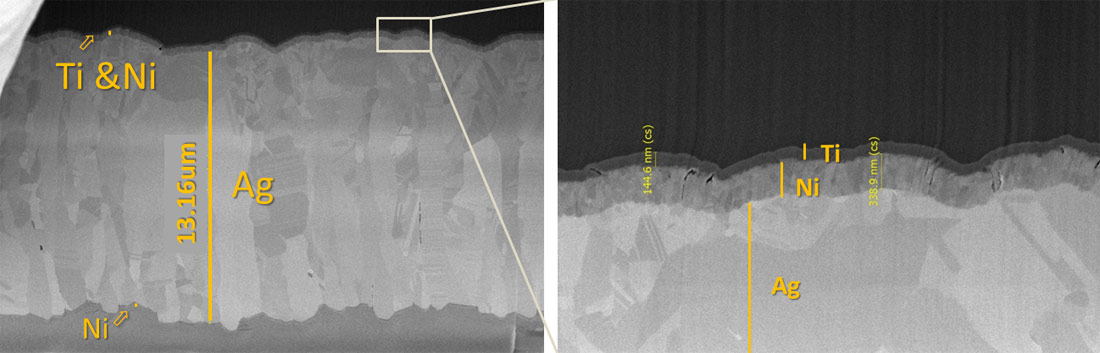

- The evaporator provided by iST may come up with Ag up to 50um thick.

- Using dual cryo-pumps to provide the high-vacuum environment for metal growth.

- Various target options, tailor-made targets available on demand.

- A team of engineers with diversified experts including front end wafer foundry, wafer thinning and backend packaging house, knowledgeable and experienced in process integration and analysis in phases from front through middle to back and well-prepared to assist customers in accelerated development, troubleshooting, and mass production stabilization.

Case Sharing

- Existing thickness options: 10~15um in mass production now, with thickness subject to customer requirements; 16~50um thickness in development, development and verification subject to customer requirements.

- Applicable to 8″/6″ P- or N-type wafers.

- An optimum combination when aligned with Taiko Wafer to reduce warpage.