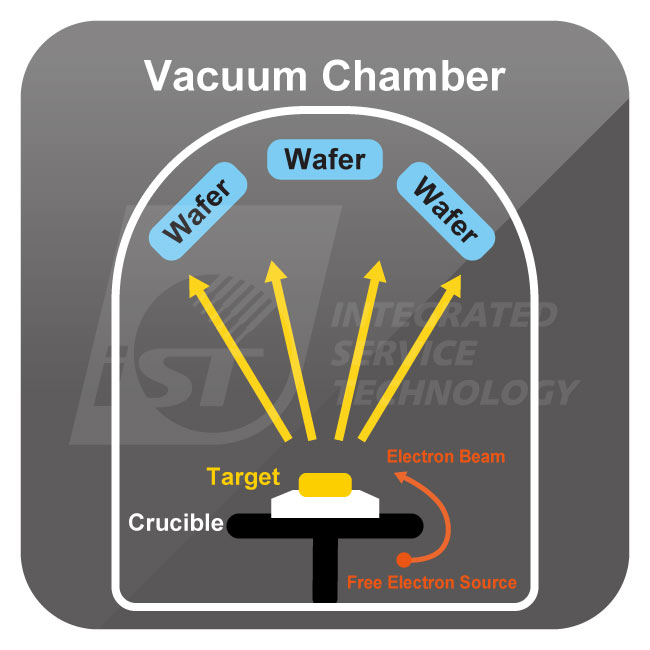

During the backside metallization (BM) of wafer thinning process, the Metal Evaporation for Backside Metallization heats up the desired target with electron beams in a high-vacuum environment to adhere vaporized targets to the heated surface of the wafer.

Metal Evaporation for Backside Metallization

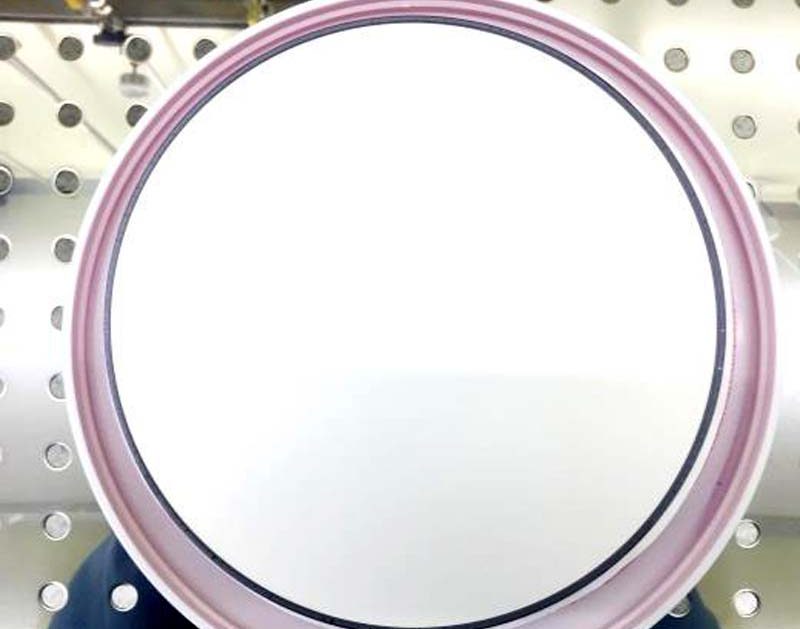

Feed wafers after successful IQC (Incoming Quality Control) into the evaporator with slugs in compliance with types and thickness given by the customer; execute Metal Evaporation and Alpha Step measurements on the sample pieces in same batch; then execute Non-destructive XRF measurement to check individual metal layers before OQC (Outgoing Quality Control) according to customer requirements. The BGBM process finished at this step.

The Superiority of iST

- Using dual cryo-pumps to provide the high-vacuum environment for metal growth.

- Varieties of target options, tailor-made targets available on demand.

- Measurement after evaporation: the Alpha Stepper adopted by the industry for total thickness measurement and non-destructive XRF measurement of the thickness of individual metal layers in a multi-layer structure.

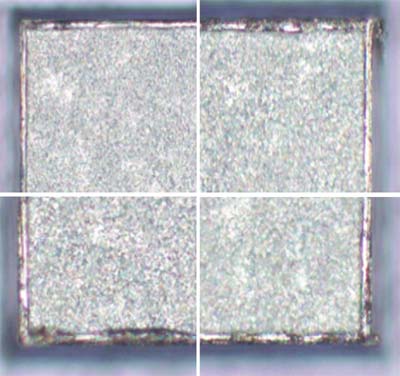

- Good metal adhesion via evaporation; the reliability verification under conditions of 85oC temperatures, 85% relative humidity, and 500 hour exposure time show non-metal peeling.

- A team of engineers with diversified experts including front end wafer foundry, wafer thinning and backend packaging house, knowledgeable and experienced in process integration and analysis in phases from front through middle to back and well-prepared to assist customers in accelerated development, troubleshooting, and mass production stabilization.

Case Sharing

- Existing metal options: Ti / Ni / Ag, Ti / Ni / Ti / Ag, Ti / Ni / Ag / Ni, Ti / Ni / Ag / Sn with thickness subject to customer requirements.

- Applicable to 8″/6″ P- or N-type wafers.

- Other combinations of metals available through joint development with the customer.