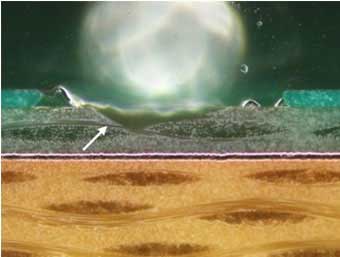

PCBs employed by base station-relevant communication equipment and cloud servers have to be of high frequency material featuring a low dielectric constant and dissipation factor to meet the requirements of high frequency and high speed mandated by 4G/5G and the IoT. There is one problem. The resin and fiber glass contained in specially designed dielectric materials suffer weak bonding strength which may lead to risks of pad cratering.

The Superiority of iST

Case Sharing

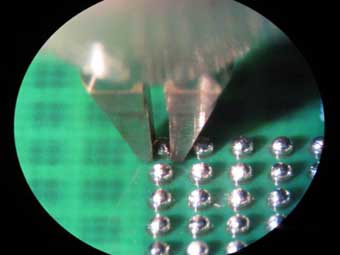

- Cold Ball Pull Test(CBP Test):

The CBP test determines the strength of high frequency and high speed and ordinary materials, as well as assessing the performance of individual materials under different process settings (IPC-9708) by detecting cracks in PCB materials in PCBs due to mechanical stress or broken surface beneath the pad with mounted components.

Contact Window | Mr. Chen/Pat | Tel:+886-3-5799909#6418 | Email:web_BLR@istgroup.com