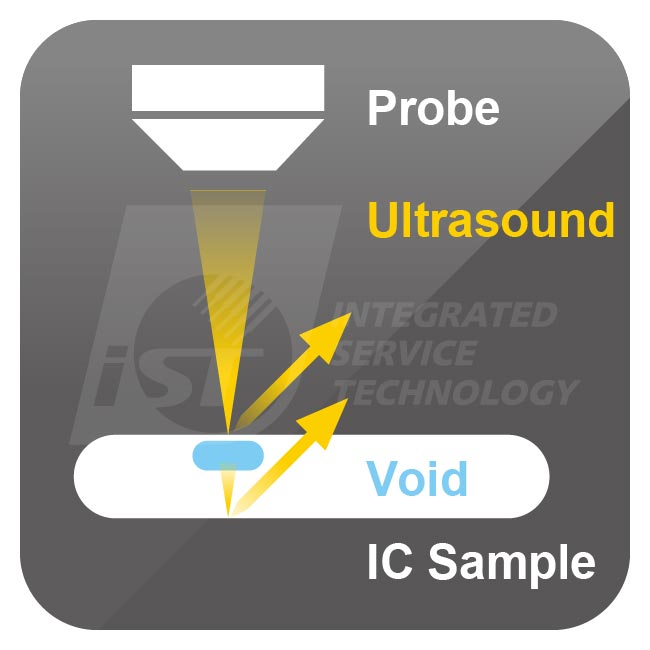

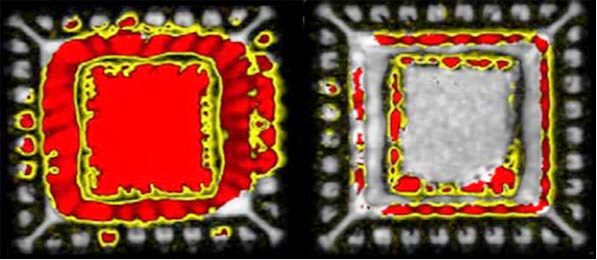

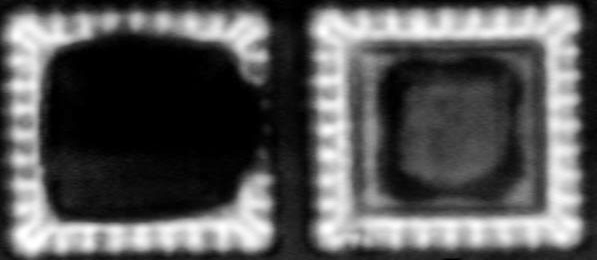

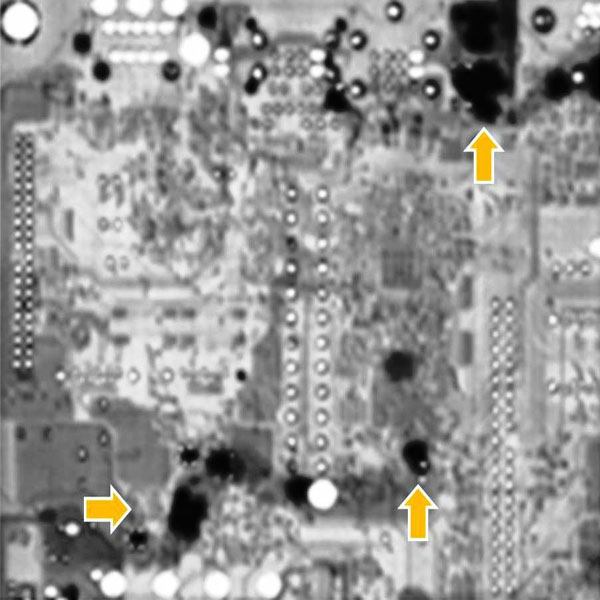

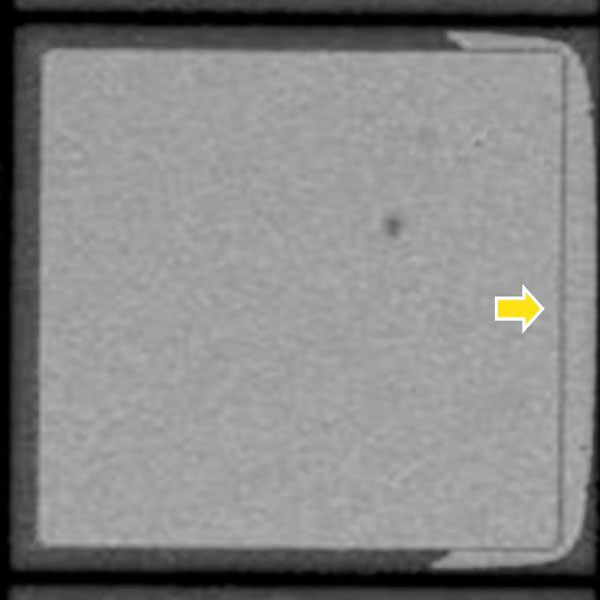

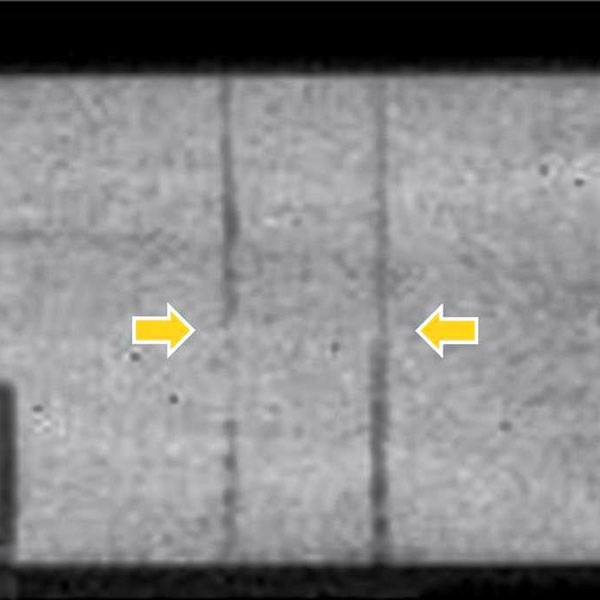

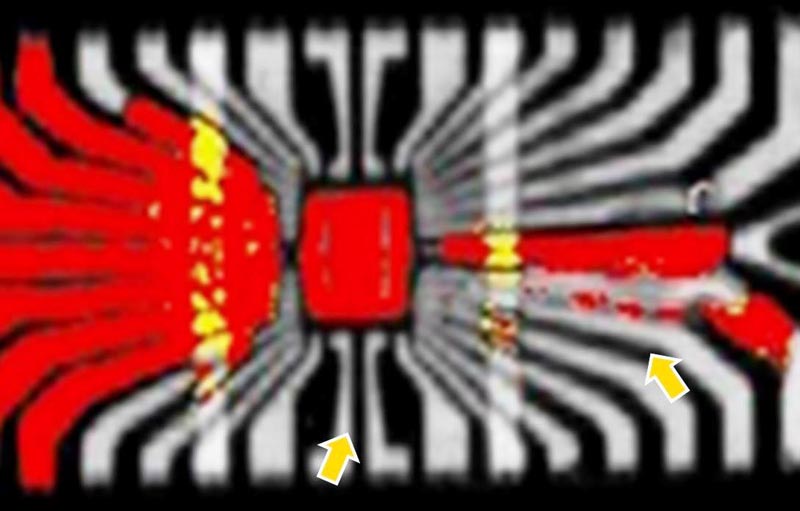

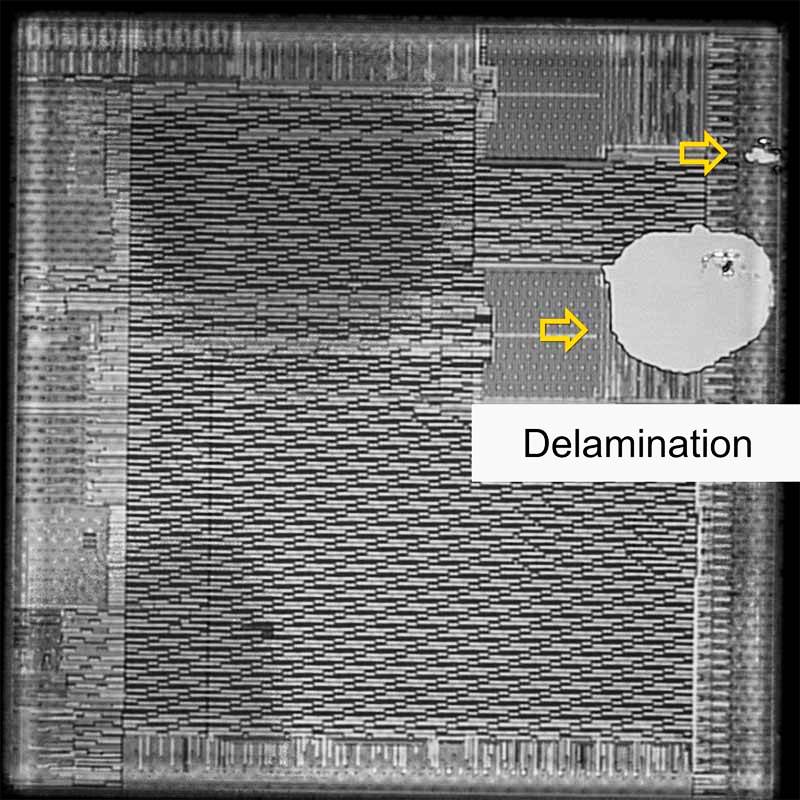

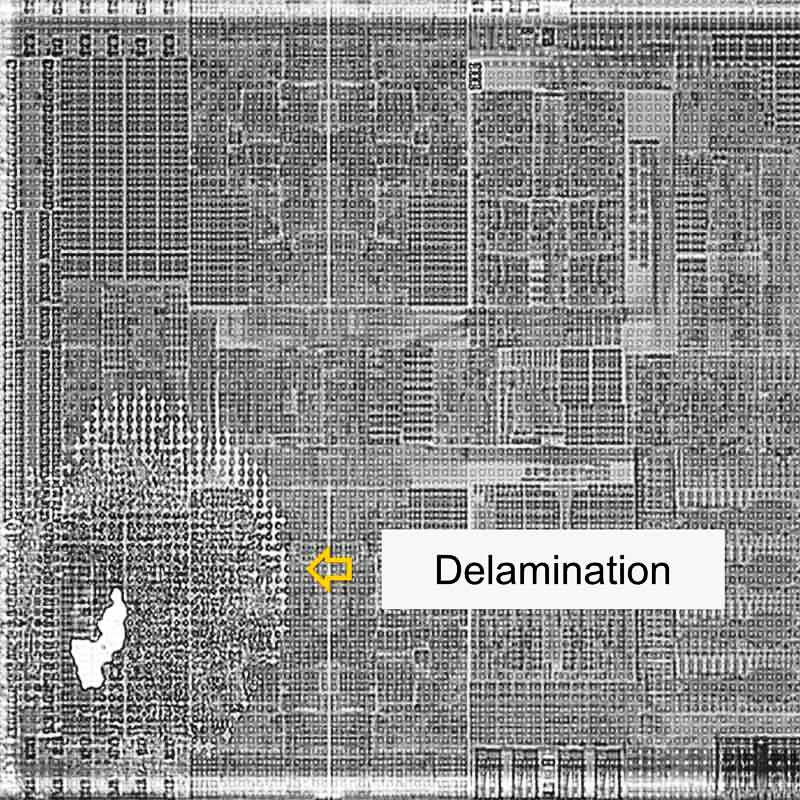

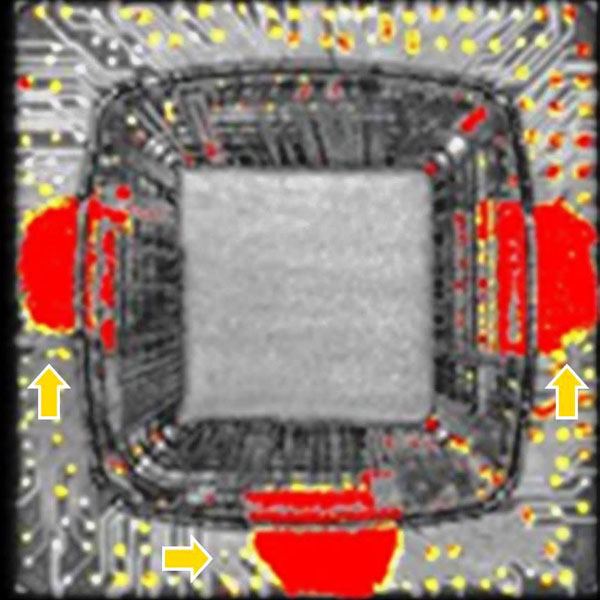

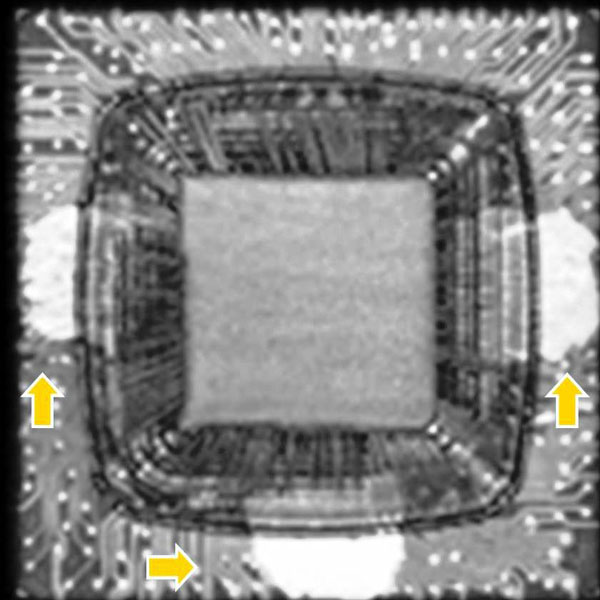

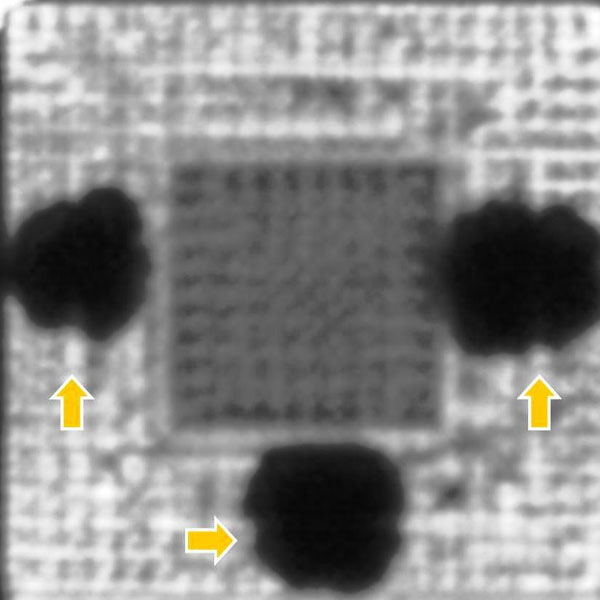

Scanning Acoustic Tomography (SAT), is an analyzed tool to analyze the material interface quality or behavior by means of different material characteristics in reflection speed and energy from ultrasound signals transmission. When contacting the bonding interface of different materials, part of the ultrasound signals will reflect back to the detector and part of the ultrasound signals will penetrate the bonding interface. When contacting air (voids), 100% of signals will be reflected to the detector to form the image with arrowed areas

When sound signals are transmitted, using pure water as the medium, and hit the interface of different materials, part of the signals reflects and part penetrates. The machine then collects the signals and forms them into images.

The Superiority of iST

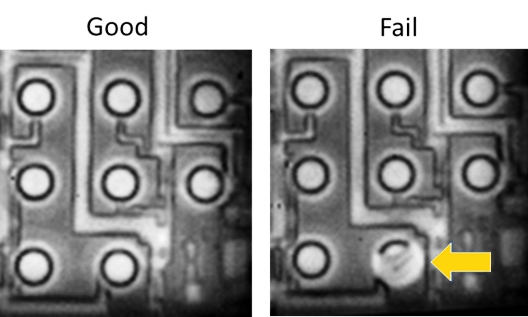

Case Sharing

Contact Window | Ms. Chen/Lena | Tel:+886-3-5799909#6570 | Email:web_nde@istgroup.com