The Superiority of iST

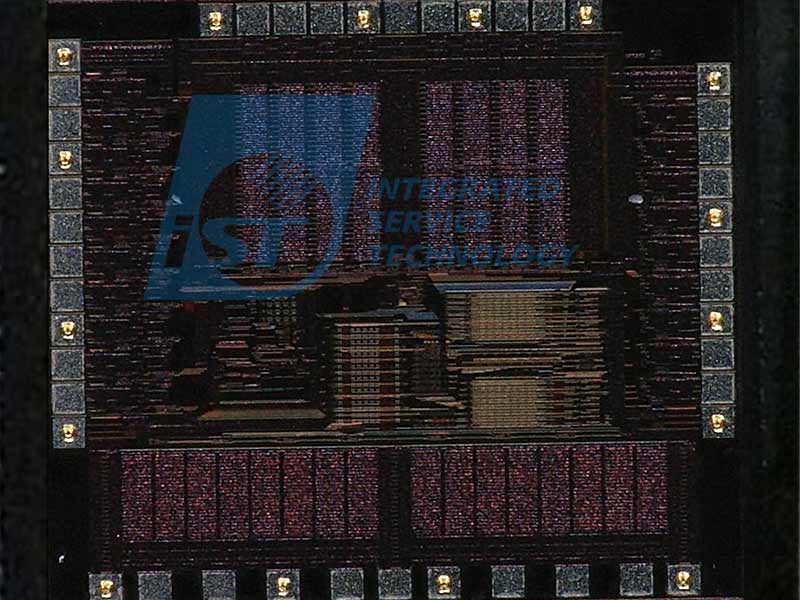

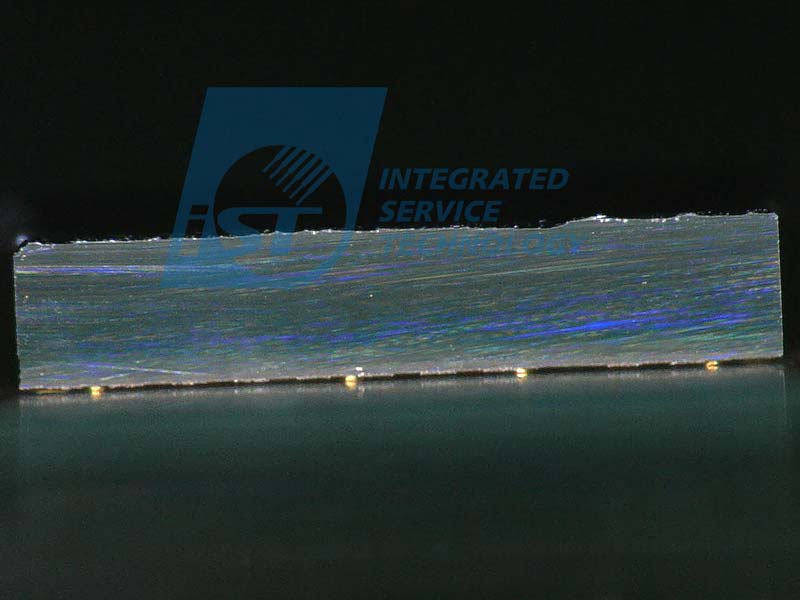

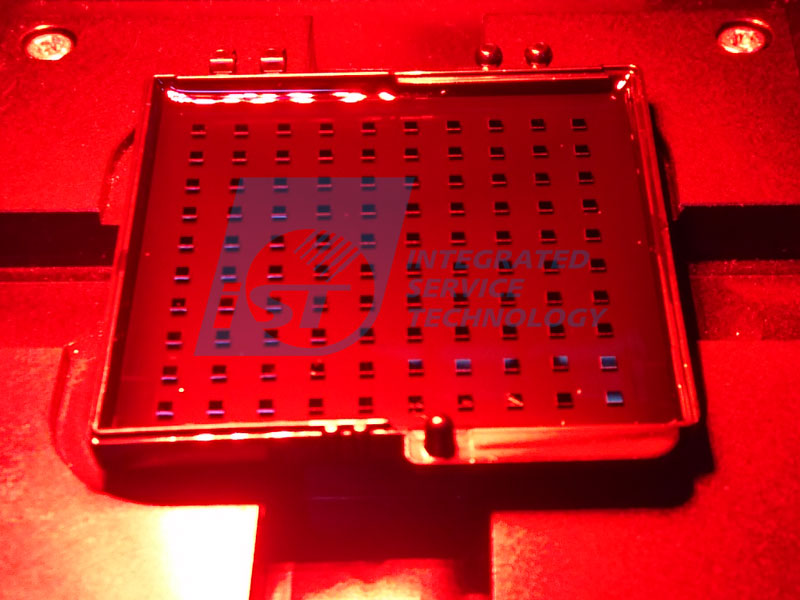

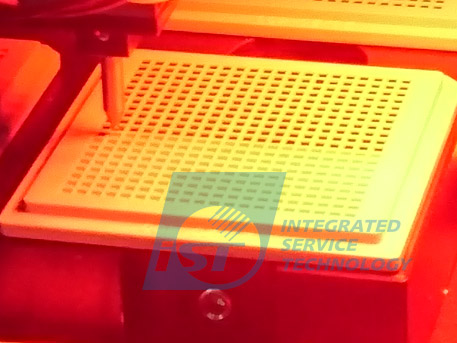

iST offers packaging process such as, die sawing, die bonding and wire bonding, following up with one-stop solution of high quality verification and analyses to effectively shorten the sample preparation time.

Case Sharing

- Wafer frame pick up and place waffle pack sorting

- Wafer frame pick up and place wafer frame

- Wafer map die sorting

- Die flip sorting

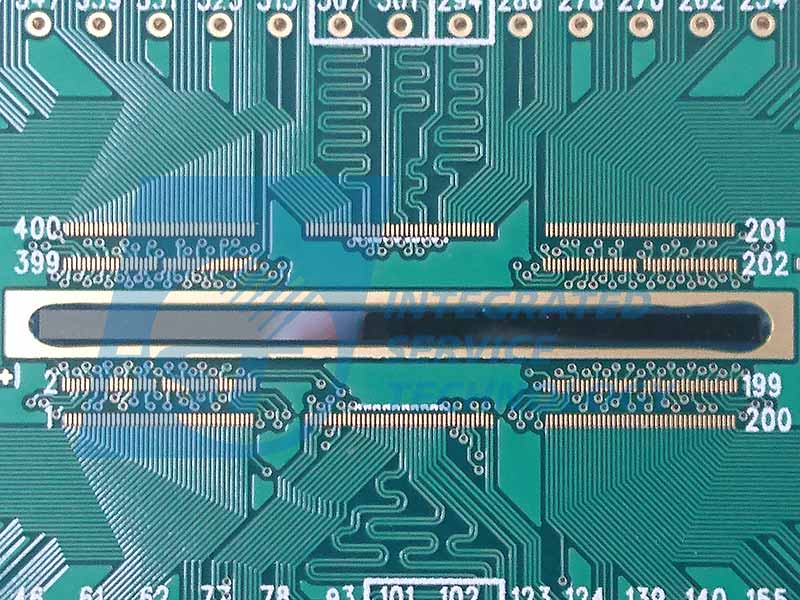

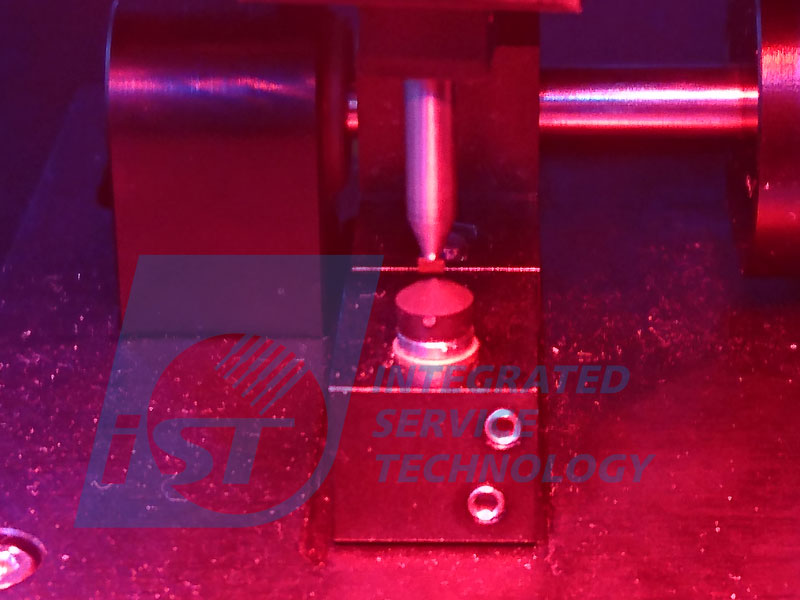

- Adhesive dispensing and die bonding

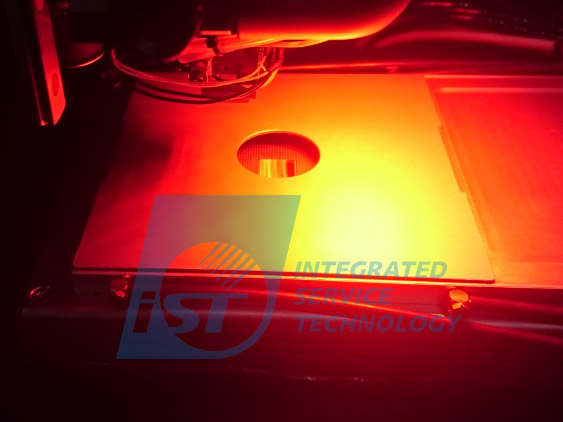

- Thermocompression die bonding

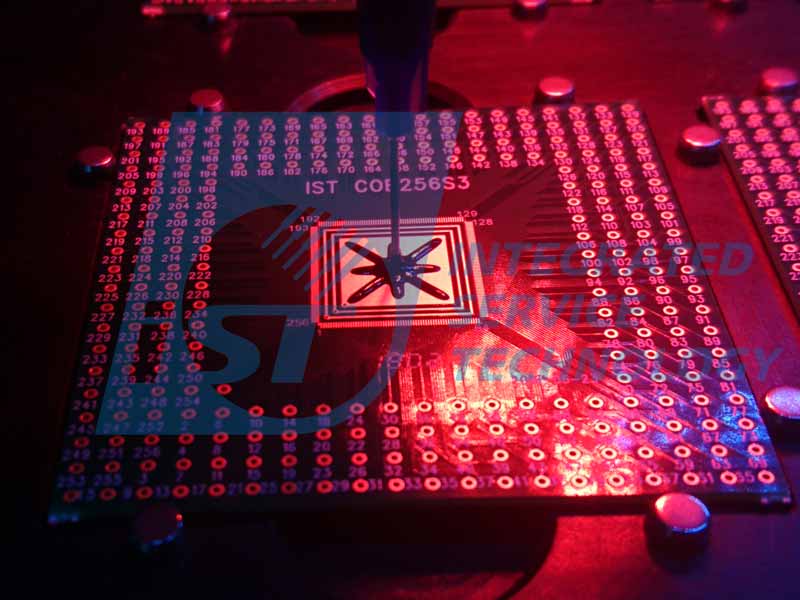

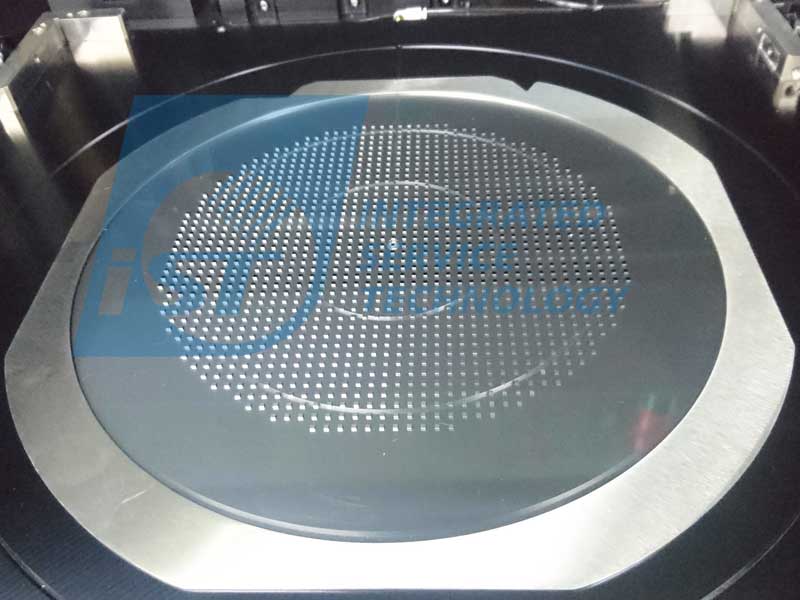

- High precision die bonding process

- Flip chip die bonding

- Eutectic die bonding

- Semiconductor industry

- LED industry

- Optoelectronics industry

- MEMS industry

Contact Window | Mr. Yang/Benson | Tel:+886-3-5799909#6862 | Email: eb_ass@istgroup.com