Electro-less Plating Process

Wafers provided by the customer shall be fed into electro-less plating for metal deposits according to given types and thicknesses after IQC. Pre-loaded programs in the electro-less plating machine shall follow the following steps: 1. Auto degrease wafers before micro-etching the aluminum pad (Al Pad). 2. Execute zincation procedure twice: execute the first zincation followed by zinc micro-etching and then execute zincation again afterward. 3. Execute electro-less plating of ENEPIG with Ni/Pd/Au before OQC.

The Superiority of iST

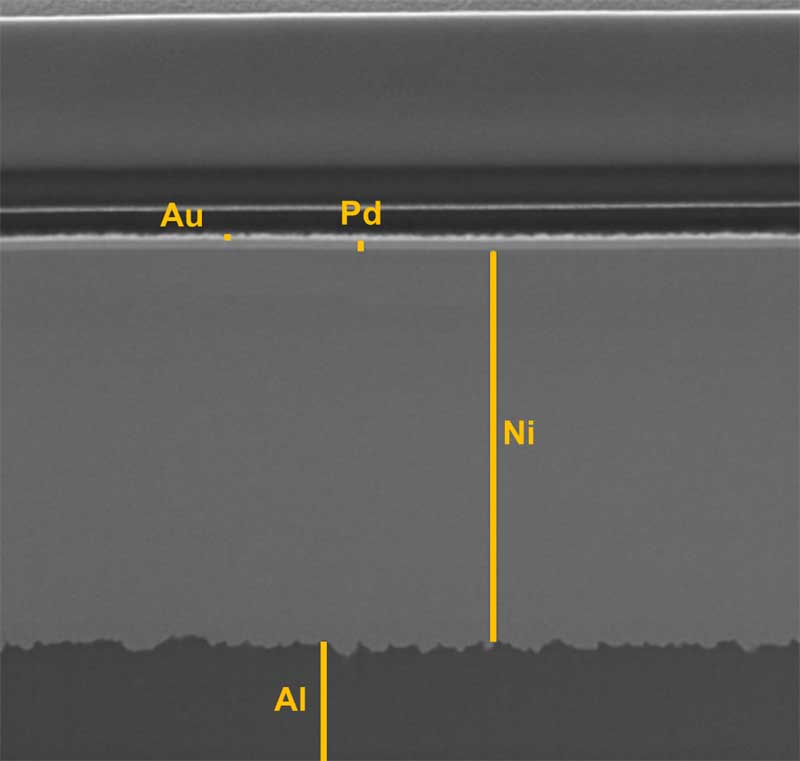

- In addition to electro-less plating of ENIG, iST may provide electro-less plating of ENEPIG as required by the customer; palladium-covered nickel may prevent the latter from over etching and provide better metal contact surface than ordinary electro-less plating ENIG.

- Reduce production time by removing the photolithography/etching/sputtering operations.

- An unique engineering services company providing electro-less plating and BGBM integrated processes in Taiwan.

- A team of engineers with diversified experts including front end wafer foundry, wafer thinning and backend packaging house, knowledgeable and experienced in process integration and analysis in phases from front through middle to back and well-prepared to assist customers in accelerated development, troubleshooting, and mass production stabilization.