The superiority of iST

iST offers sample dicing, wire bonding, ceramic or COB assembly followed by premium one-stop solution services for ESD/OLT analysis and verification to minimize test sample preparation time significantly.

Case Sharing

- PCB development and packaging projects

- Rework of rejected ICs sample preparation, backside sample preparation

- Planning of small-quantity production

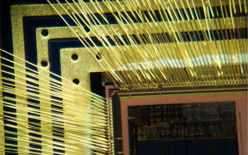

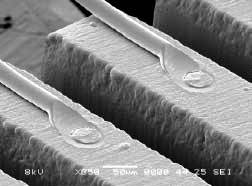

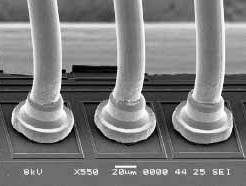

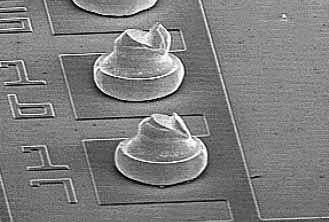

- Wire bonding/molding/capping

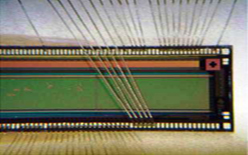

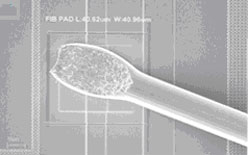

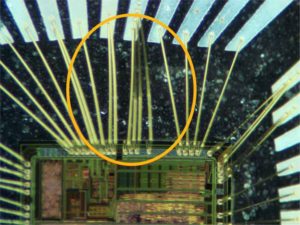

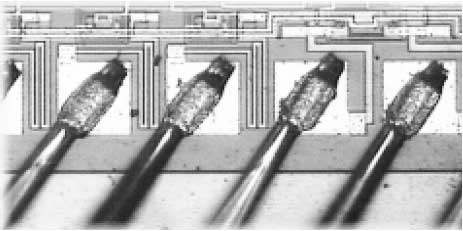

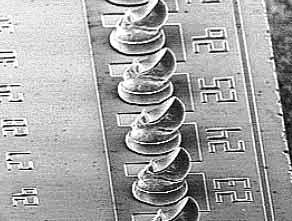

- Varieties of wire bonding methods: driver IC, COB, FIB Pad, chip-to-chip, ball mounting

- Wire bonding verification(Open/Short test)

Contact Window | Mr. Yang/Benson | Tel:+886-3-5799909#6862 | Email: web_ass@istgroup.com