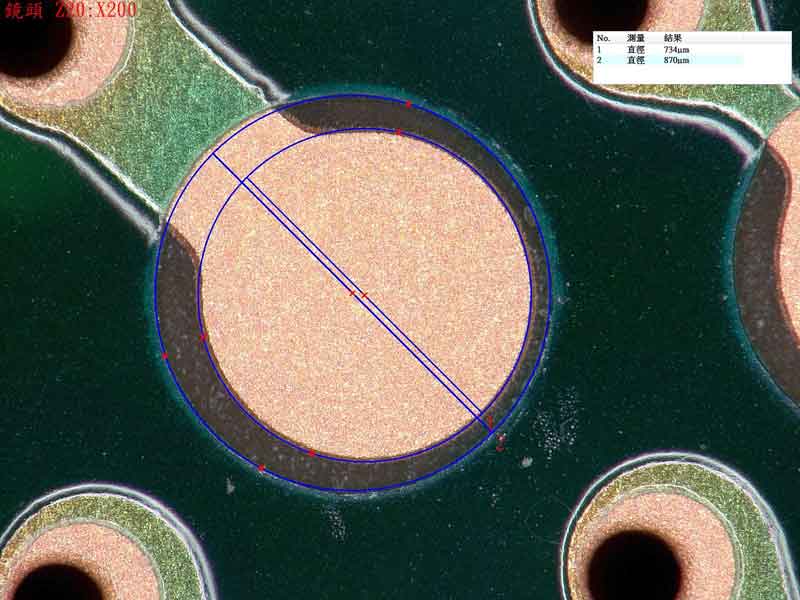

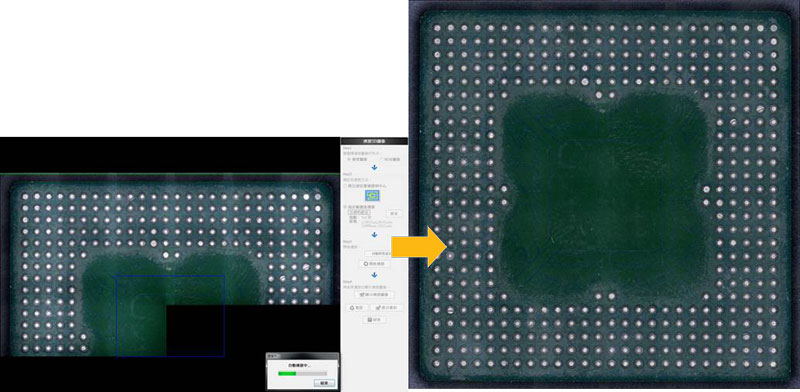

3D Optical Microscope (3D OM) captures the reflection of visible light from object surface with optical zoom-in and zoom-out and CCD for surface pattern observation and dimension analysis and measurement.

The Superiority of iST

Case Sharing

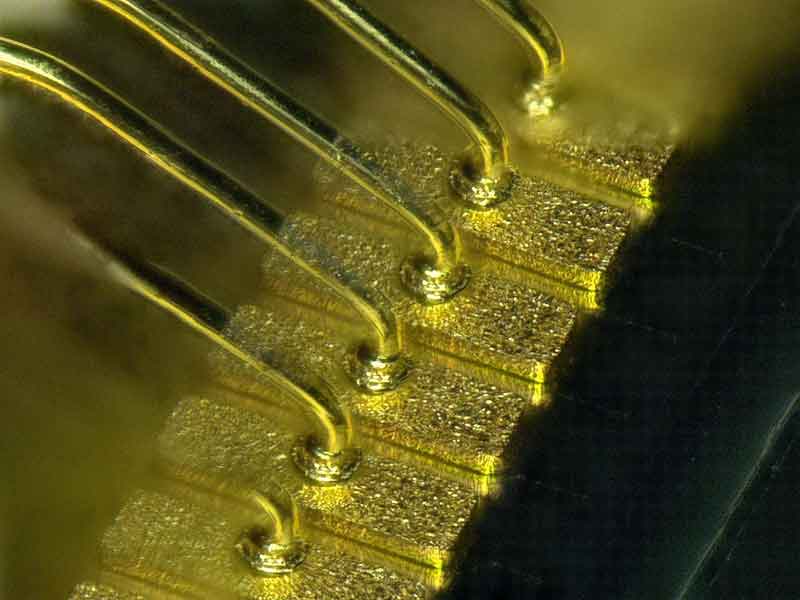

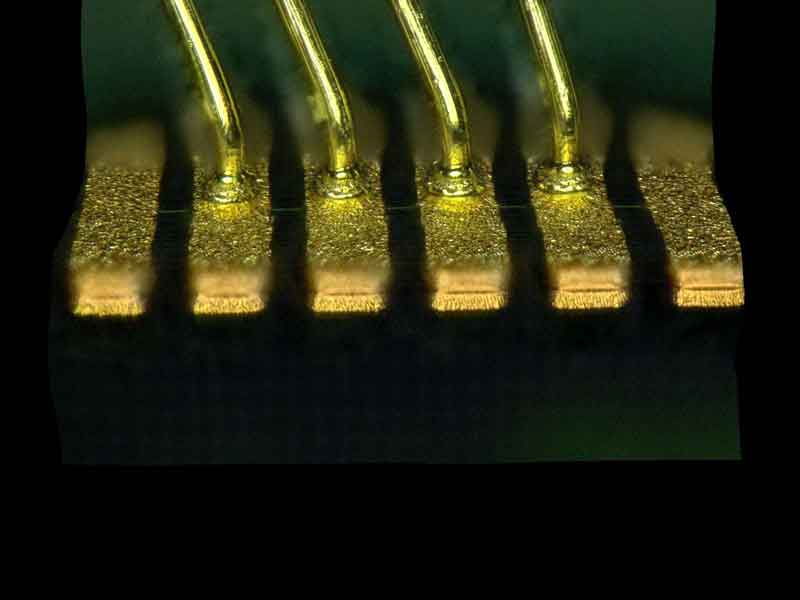

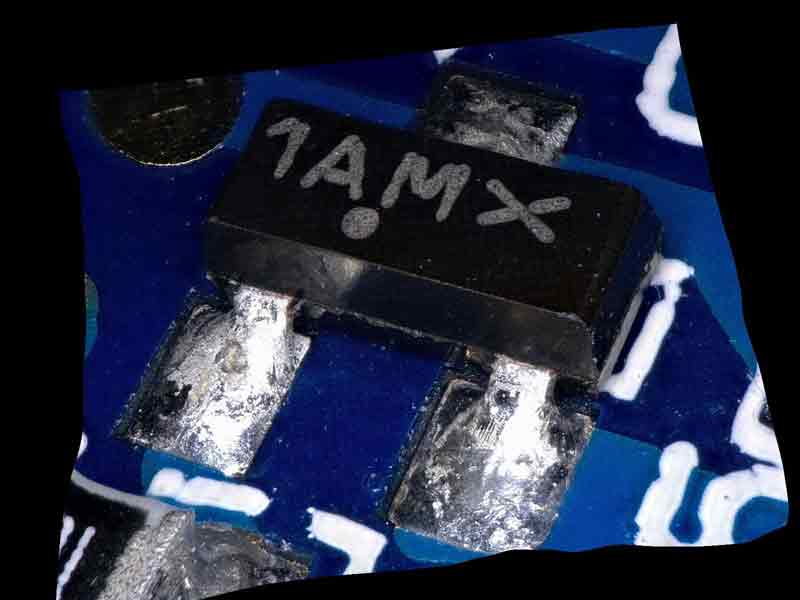

- Detection of part IC package defects, such as appearance integrity, the black gum cracks, pin deformation or discoloration.

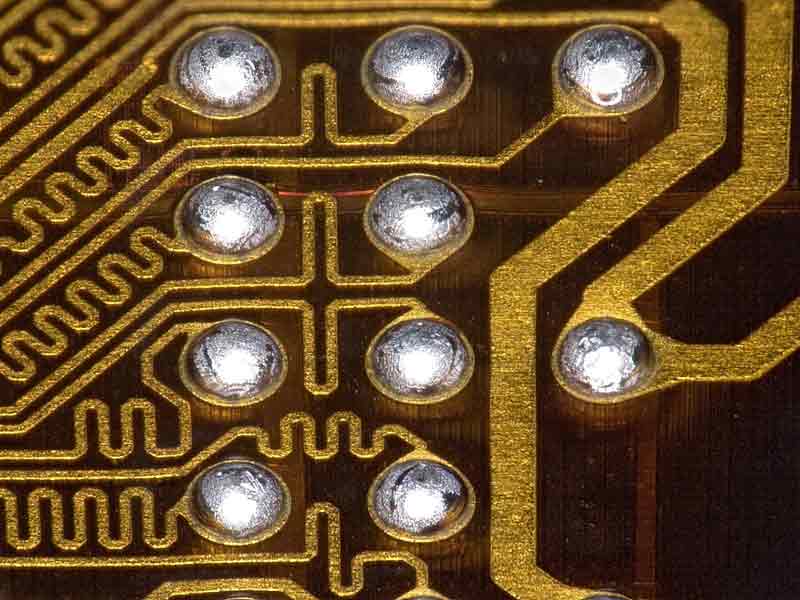

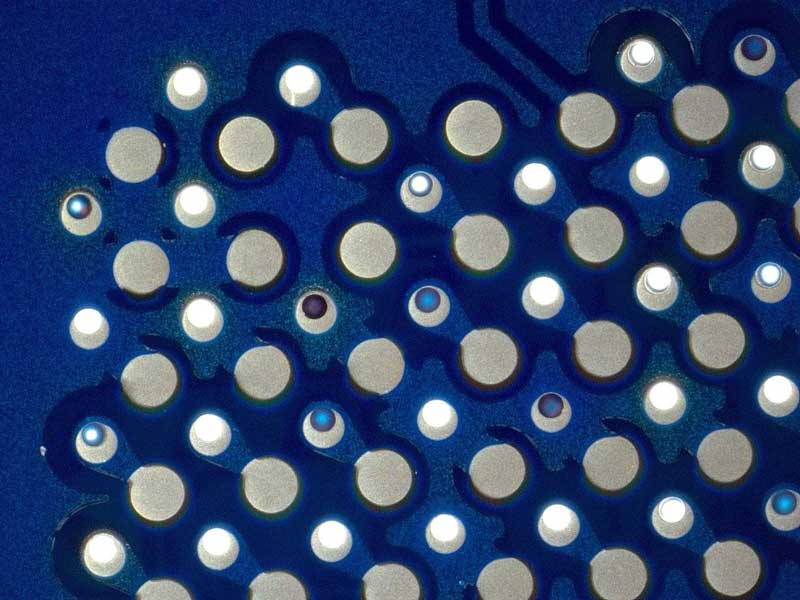

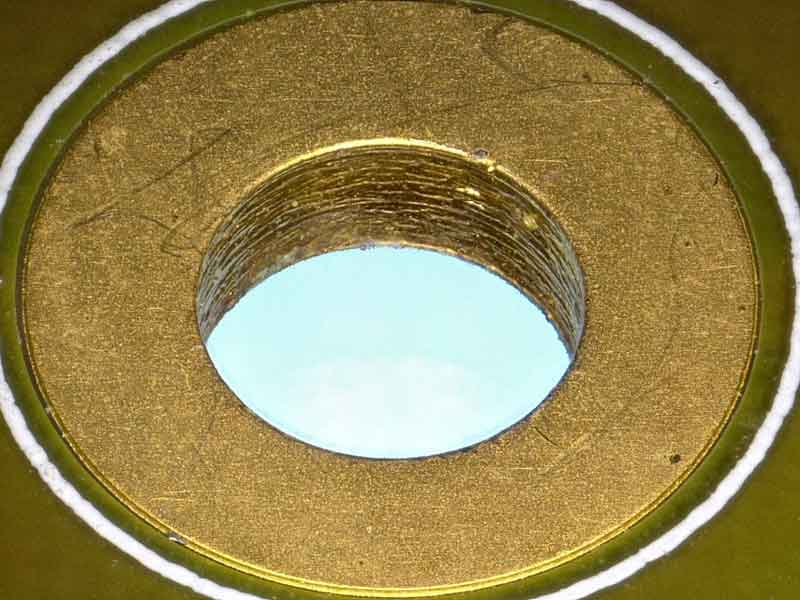

- Detection of potential PCB defects, such as nodules, weave exposure, glass fiber exposure, solder mask, text.

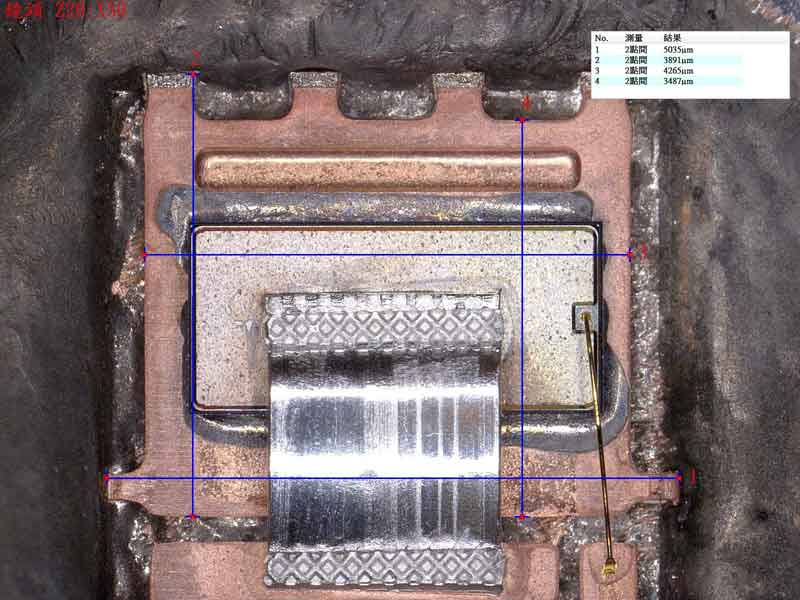

- Detection of potential detects in electronic products, such as poor soldering.

- Solder ball integrity inspection of BGA and flip chip packages, such as ball deformation.

- Appearance check and analysis of active and passive components.

- Analysis and measurement of all materials.

Contact Window | Ms. Chen/Lena | Tel:+886-3-5799909#6570 | Email:web_nde@istgroup.com