The Superiority of iST

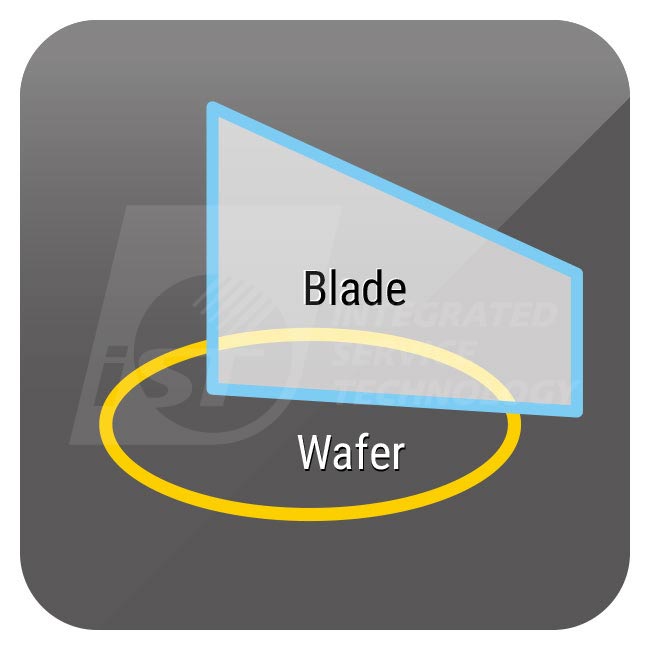

In addition to internal dicing machine for wafer of size up to 12″, iST provides one-stop high-quality solutions from sample dicing, wire bonding, ceramic packaging, to COB packaging. All these are designed to cut test sample preparation time effectively.

Case Sharing

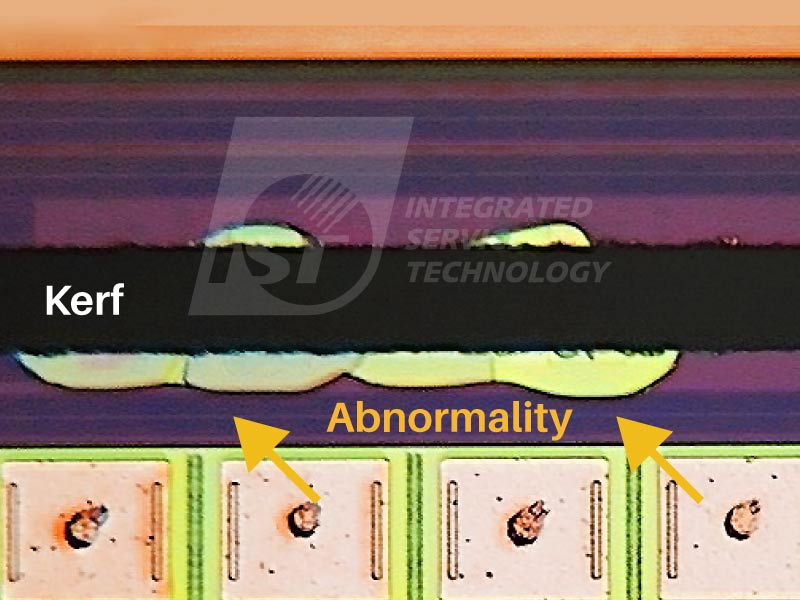

- Ordinary wafer dicing

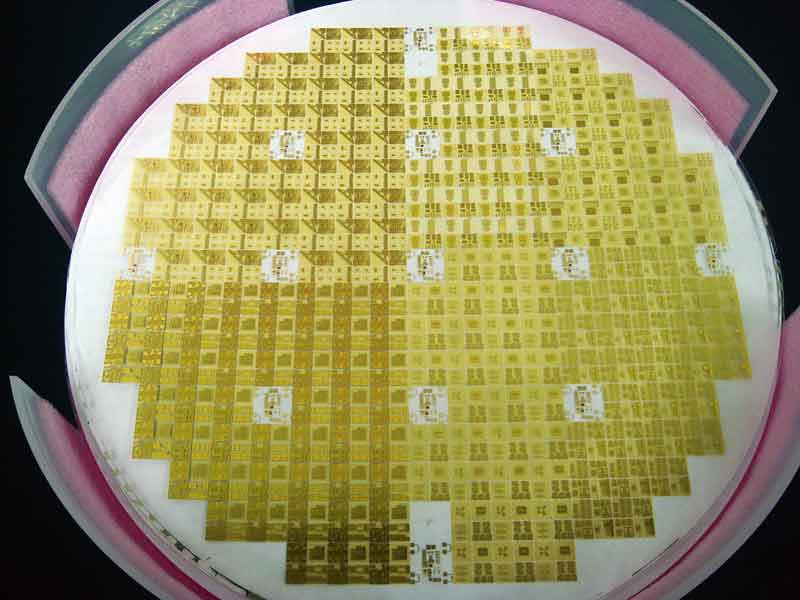

- Multi-chip wafer dicing

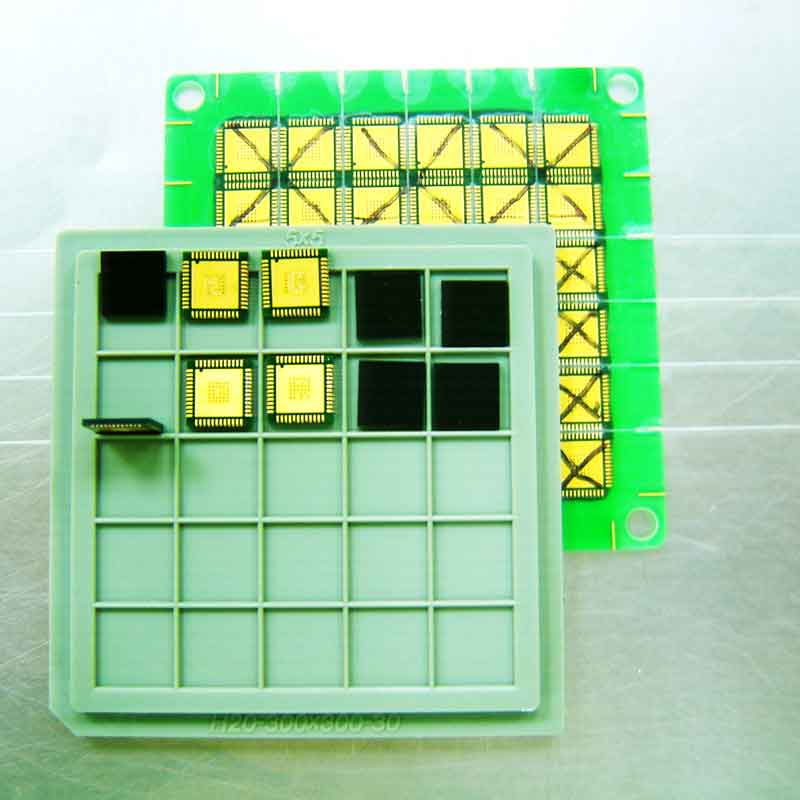

- Shared chip re-dicing

- Substrate dicing (with or without adhesive)

- Ceramic/glass board dicing

- IPD dicing

- Multi stacker wafer

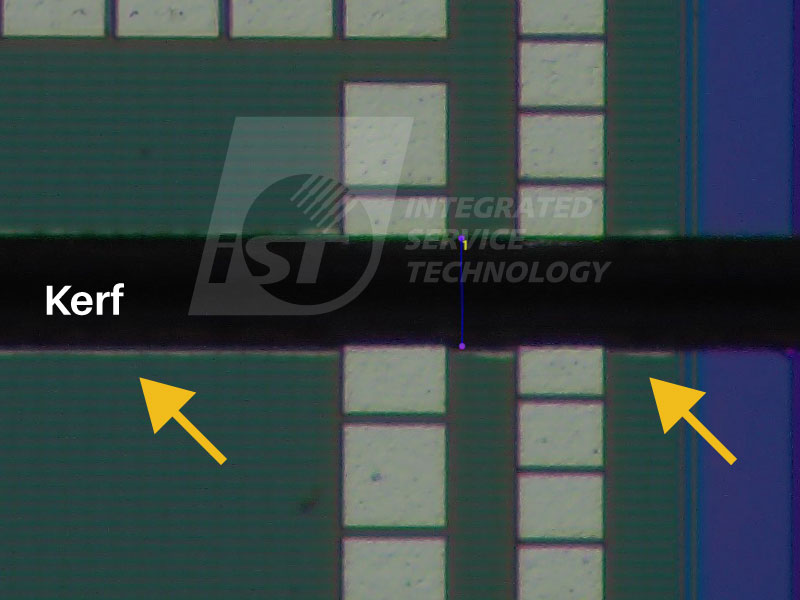

- Narrow kerf width

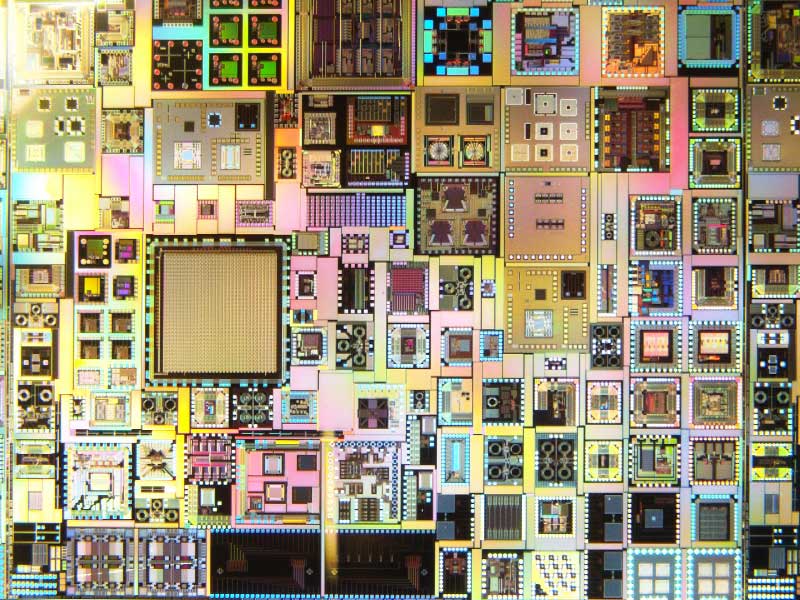

- High density wafer

Contact Window | Mr. Yang/Benson | Tel:+886-3-5799909#6862 | Email: web_ass@istgroup.com