The Superiority of iST

- A 12" wafer containable AFM machine is rare within Taiwan and mainland industry. This enables analysis without breaking the wafer and maintains its completeness for later tests.

- The NX-Wafer atomic force profilometry has the largest scan area in industry accompany with excellent image resolution.

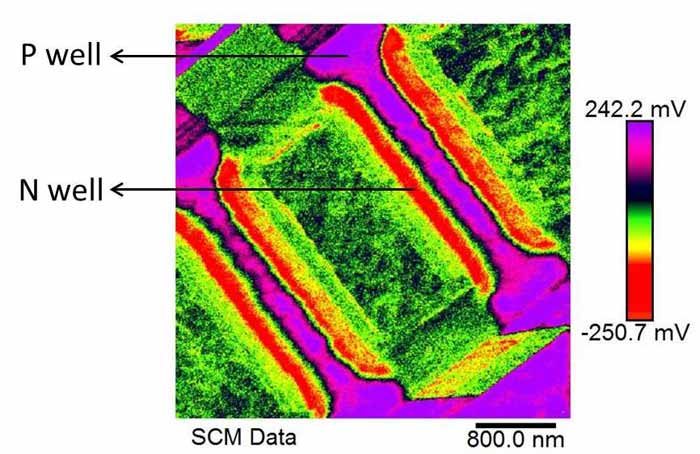

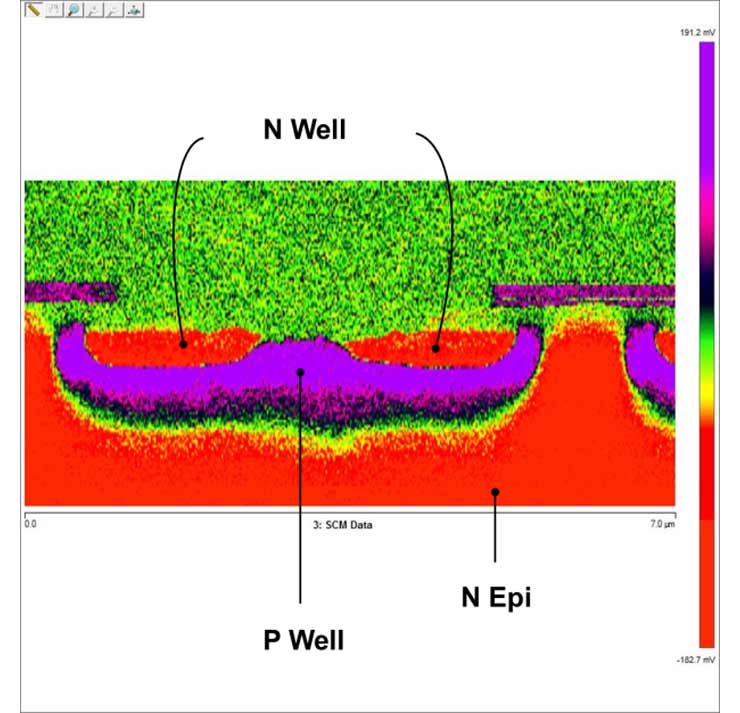

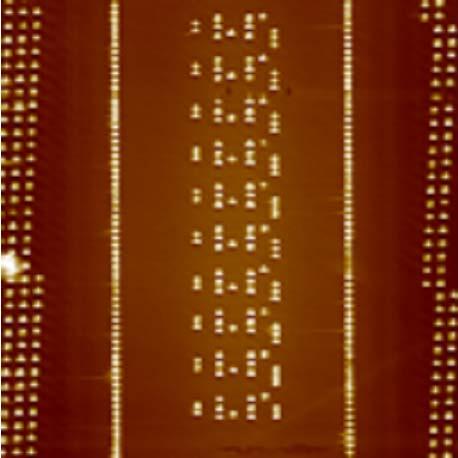

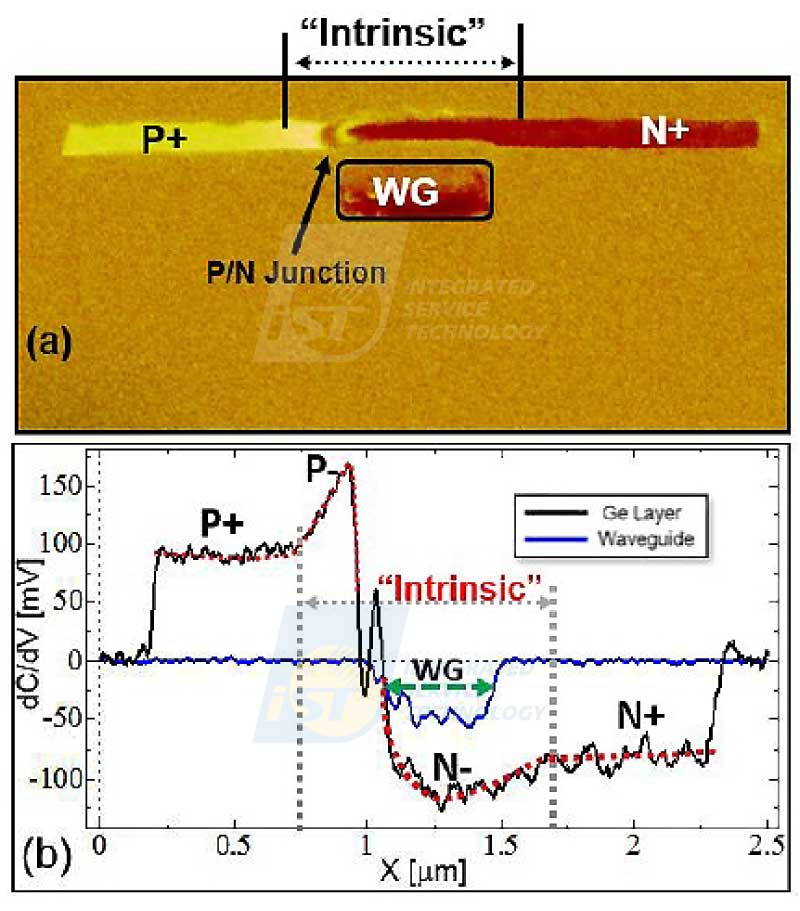

- The extra microscope with additional functions enables a still wider scope of analysis applications, i.e., CAFM (Conductive Atomic Force Microscopy) and SCM (Scanning Capacitance Microscopy).

| AFM | AFM profiler | CAFM | SCM | |

|---|---|---|---|---|

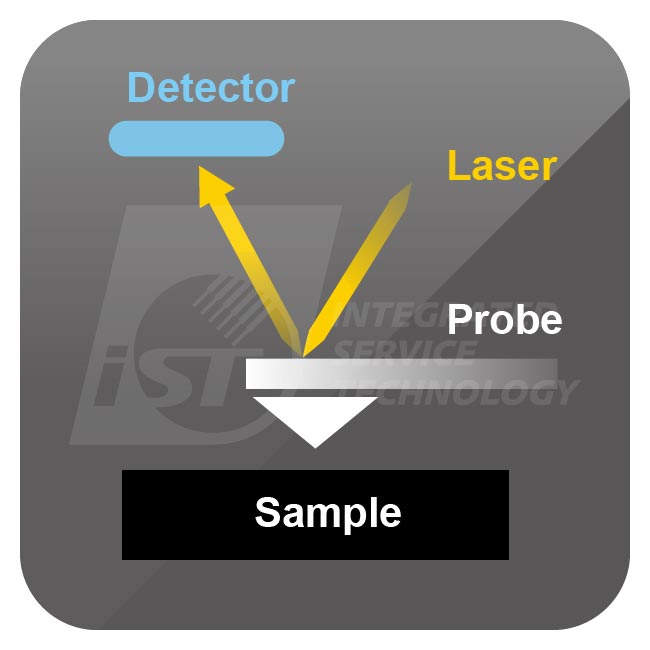

| Analysis mechanism | Measure the surface structure and looks by atomic forces between the probe tip and sample | The probe applies voltage on its tip or sample to get the current strength at the sample surface | Get the differential of capacitance signals with a conductive probe, convert them into 2D doping image distribution | |

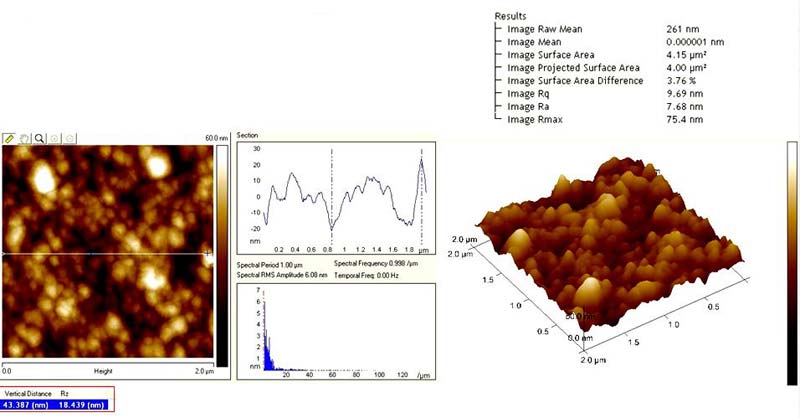

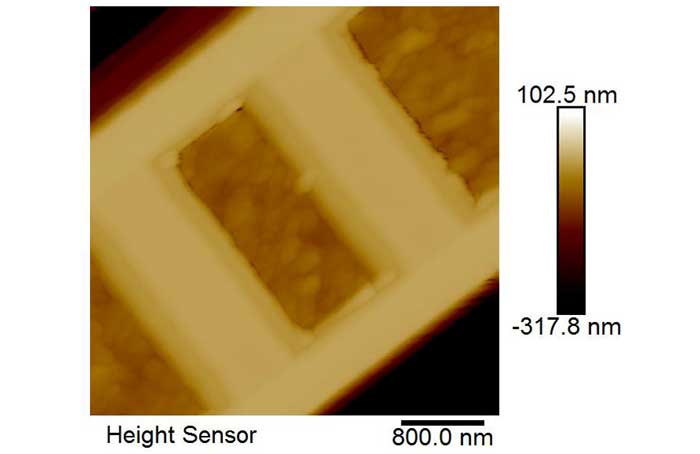

| Analysis application | 1. Material surface roughness measurement and structure observation 2. Material surface 2D/3D pattern image 3. Nanoscale depth analysis and dimensioning | 1. Detect over resistance or current leakage 2. Identify P+/ N+ /Poly contact 3. Measure single point I-V curve | P-N type zone and border | |

| Equipment specification | 1. Sample dimension: (mm) 200 x 200 x 15 2. 300 mm x 300 mm (12" wafer) Compatible 3. Analysis scope (um): 90 x 90 x 5 | 1. Sample dimension:300 mm x 300 mm (12" wafer) Compatible 2. Maximun scanning range:50000 um | 1. Magnification ratio: 107~1011 2. Bias voltage range: -10V~10V | 1. Plane resolution: 20nm Doping concentration 2. Range: 1015~1019 atom/cm3 3. Scanning range: 90 * 90um / with height in 2cm |

Case Sharing

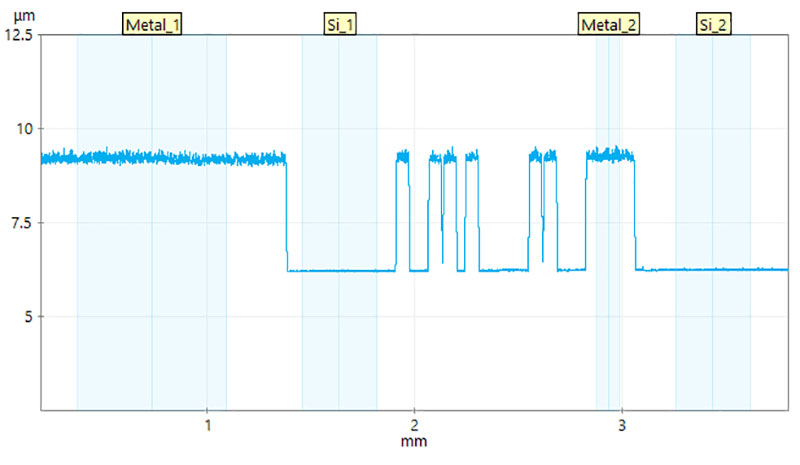

The maximun 50000 um long range profiler with atomic resolution can provide the details of surface topography and roughness information.

- Membrane roughness tests

- Structural study of micro surfaces

- 2D/3D material surface topography

- Nanoscale step height analysis

- Depletion Analysis in Silicon Photonic Devices

Bruker Dimension Icon

Bruker INNOVA

Park System NX-Wafer

Contact Window | Ms. Wu/Ping | Tel:+886-3-5799909#6183 | Email:web_ma@istgroup.com