Rubber Socket (Pressure Conductive Silicone Rubber, PCR) is a type of conductive interface material consisting of conductive powder uniformly dispersed within silicone rubber. Without any soldering connection, a stable electrical path is formed under applied pressure, enabling non-destructive electrical contact between the chip and test boards.

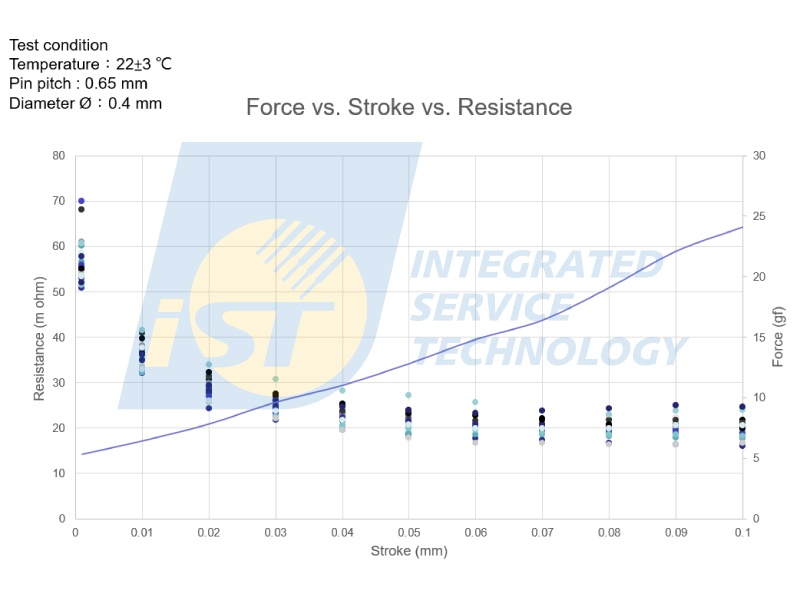

Compared to traditional pogo-pin-based contact methods, Rubber Socket (PCR) offers superior signal integrity and controlled contact force, significantly reducing the risk of damaging chip contact balls during testing.

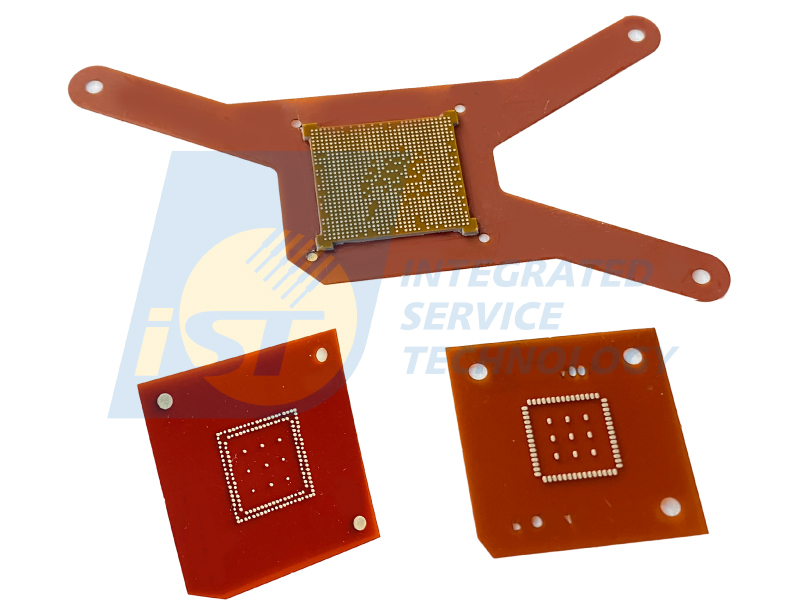

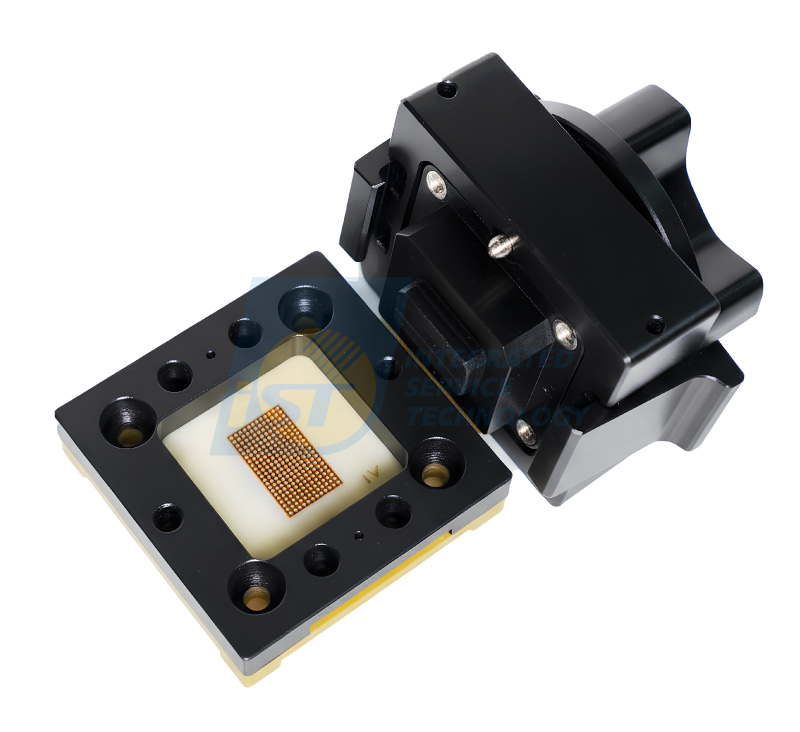

Rubber Socket (PCR) provides multiple benefits—including high-frequency transmission capability, low contact resistance, minimal mechanical impact on chip contact balls, and ease of replacement—making it especially ideal for advanced package testing in high-speed and high-frequency applications. It is widely used in Burn-in Boards, Load Boards, and System Level Test (SLT) sockets. By integrating Rubber Socket (PCR) into the test socket design, test accuracy and yield are enhanced while ensuring chip protection.

- Burn-in Board Sockets: High-temperature endurance and long lifecycle.

- Load Board (Final Test Stage): Stable low-pressure contact, minimizes contact balls damage during production testing.

- System Level Test (SLT): Designed for extended reliability tests with low contact resistance.

- PCB to Substrate Interface: Supports fine-pitch designs, solder-free, easy replacement, and highly stable connectivity.

Contact Window | Ms. Lin/Aaliyah | Tel:+886-3-5799909#8890 | Email:HWBU_Sales@istgroup.com