The Superiority of iST

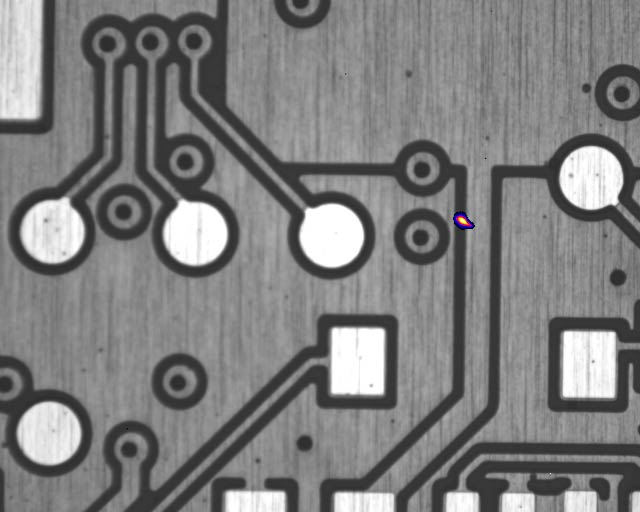

Case Sharing

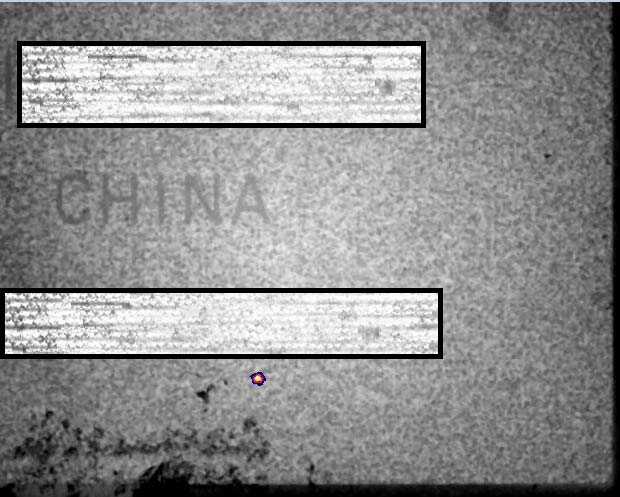

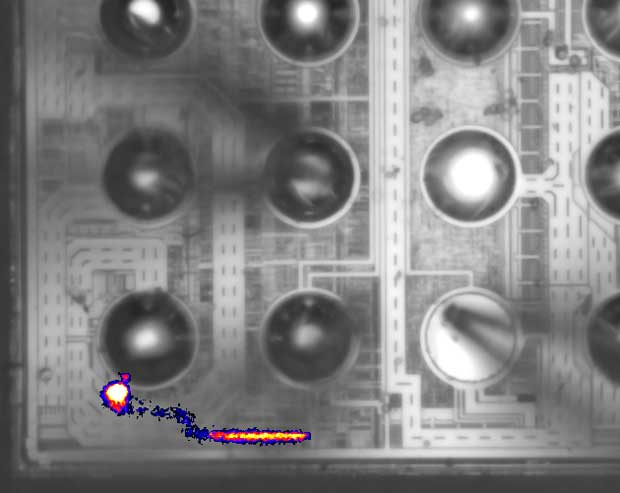

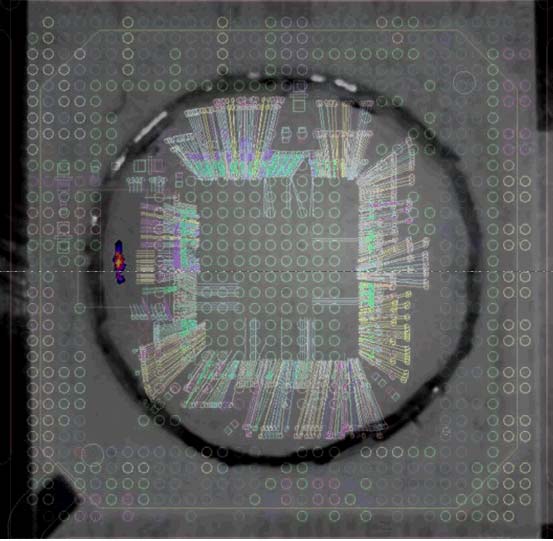

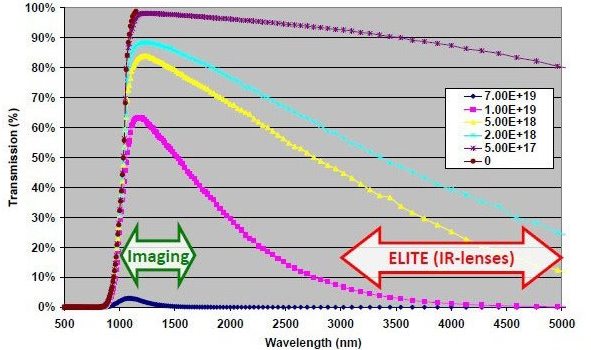

Effect of doping on transmission through silicon:

Transmission for 100um SI and different doping levels

- IC semiconductor industry

- TFT LCD panel industry

- PCB/PCBA industry

Contact Window | Ms. Liu/Sylvia | Tel:+886-3-5799909#6780 | Email:web_EFA@istgroup.com