Extending Verification Expertise to Deliver Professional Hardware Design and Integration Services

With over 30 years of practical experience in reliability testing, materials analysis, and failure analysis within the semiconductor industry, iST understands that successful testing under extreme conditions such as high voltage, high frequency, long durations, and high temperature requires more than just analysis equipment and manpower. It also relies heavily on the precise design and integration of front-end “test interface hardware.”

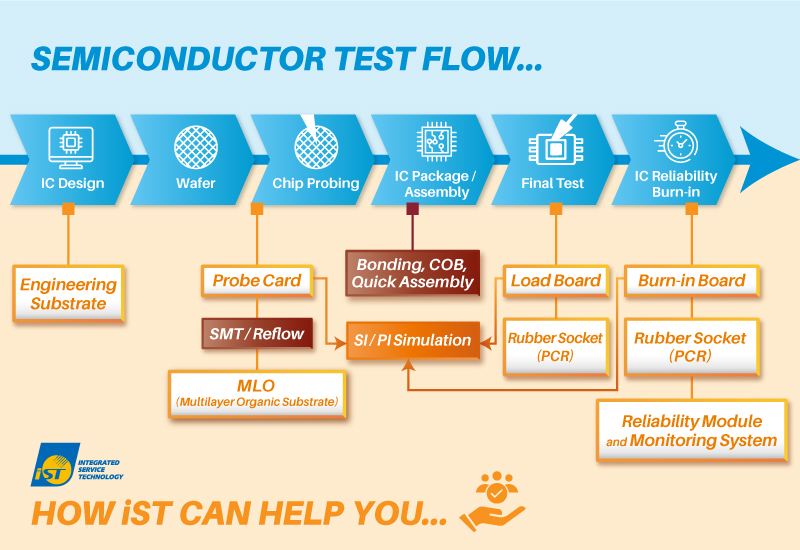

To meet these needs, iST provides comprehensive end-to-end hardware design and fabrication solutions, empowering customers to develop critical test interfaces across the entire wafer-to-packaging process, including:

- PCB Design and Fabrication: Including Burn-in Boards, Load Boards, and Engineering Substrates

- Test Sockets and Probe Cards: Manufacturing various IC sockets and high-density probe cards

- Interposer Design: Supporting advanced packaging and chip module interface design

- Burn-in and Pre-conditioning Boards: Meeting requirements for high-temperature long-duration testing and lifetime verification

- Reliability Monitoring Modules and Mechanical Fixtures: Providing customized functional modules to assist anomaly detection and enhance test stability

- High-Speed Signal Electrical Simulation Services (SIPI): Offering high-speed signal design and layout consulting through our dedicated SIPI simulation team

Precisely addressing the practical needs of customers in the high-speed signal testing

In applications such as high-speed interfaces, automotive electronics, and high-frequency AI chips, customers increasingly demand superior test board quality, stable contact performance, SI/PI integrity, and measurement consistency. iST’s hardware solutions are specifically designed for these advanced applications, effectively enabling verification engineers to achieve stable, accurate, and highly efficient testing throughout all project stages.

iST’s Three Key Hardware Verification Advantages: Tackling R&D and Testing Challenges

- Professional SI/PI Simulation Team for Enhanced Design Accuracy

iST has established an in-house SIPI simulation platform, integrating impedance and power integrity analysis from the early design stage. This ensures high-frequency signal stability, reduces reflow errors and EMI risks, and significantly saves rework and debugging time. - Comprehensive PCB Manufacturing Capability to Ensure Efficient Implementation

With our own SMT lines, reflow ovens, X-ray inspection, and flying probe testing, iST fully controls the process from board assembly to electrical verification. Completing the entire workflow under one roof effectively eliminates communication gaps and delays associated with outsourced processes. - Over 20 Years of Hardware Experience Bridging Directly to Mass Production

With thousands of hardware design and fabrication projects under our belt, iST quickly translates engineering requirements into practical boards and fixtures. We have extensive delivery experience in AI, high-speed networking, and automotive testing applications.