Issued Date:2024/10/01Carbon footprint

Issued By:iST

As companies respond to customer demands within the value chain, they are increasingly considering how to integrate and implement ESG as a key performance indicator to enhance operational outcomes. Product carbon footprint has emerged as another crucial factor, alongside quality, price, and specifications, that aligns with customer value chains. But how can businesses meet their clients’ ESG-related requirements, earn positive evaluations from stakeholders, and gain recognition from international brands?

Carbon footprint

Given that global climate change has become a critical international environmental issue, various countries and regions now have specific requirements and guidelines for carbon footprints, such as France’s ADEME (Agency for Ecological Transition) guidelines and Japan’s Carbon Footprint Program. Additionally, major international companies, including Microsoft and automotive electronics giants like Bosch, are actively promoting carbon footprint management among their suppliers to reduce the overall carbon emissions of the supply chain, in an effort to achieve their Sustainable Development Goals (SDGs). By adopting product carbon footprint practices, companies can position themselves as key partners in their clients’ ESG (Environmental, Social, and Governance) strategies, fostering long-term collaboration. However, when businesses begin calculating their carbon footprints, they often encounter challenges such as boundary setting, data collection, and quantification, which can hinder progress.

With extensive experience providing consulting services to hundreds of companies, iST has successfully helped clients obtain numerous value-added certifications, facilitating smooth entry into international industry supply chains. In this article, we will share these insights and explore how to efficiently conduct product carbon footprint calculations and reporting to meet clients’ ESG requirements, thereby helping businesses maintain a competitive edge in the global supply chain.

Carbon footprint

Carbon footprint

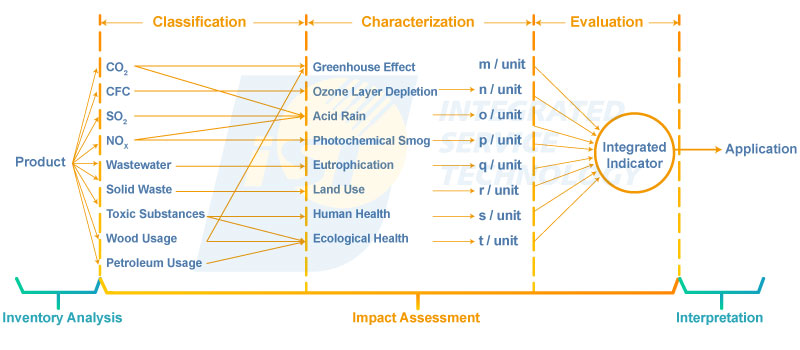

1.Product Carbon Footprint – Based on Life Cycle Assessment (LCA)

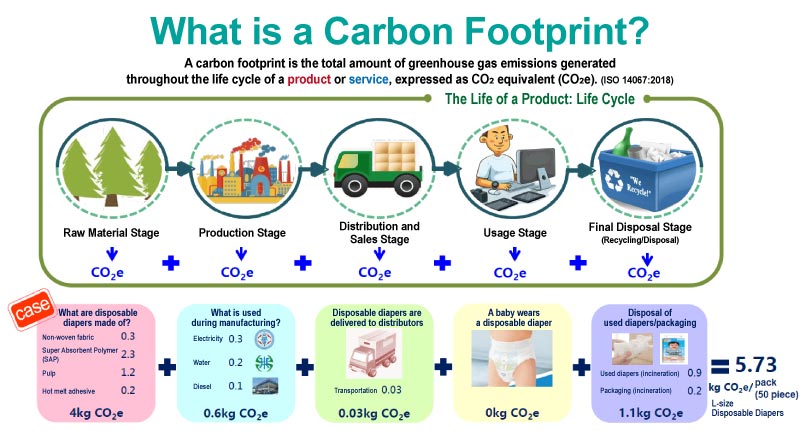

A carbon footprint is a specific environmental indicator used to quantify the direct and indirect greenhouse gas emissions generated by an activity, product, or service throughout its life cycle, typically expressed in carbon dioxide equivalents (CO₂e). The product carbon footprint is assessed based on a systematic approach defined by ISO 14040 and 14044, which evaluates the impact on global warming across the entire life cycle. This includes carbon emissions from all stages, such as raw material extraction, manufacturing, usage, and final disposal.

(1) ISO 14040:

Life Cycle Assessment – Principles and Framework provides the overall framework and principles for LCA, covering the fundamental concepts, scope, and limitations of LCA, as well as the basic steps and procedures for conducting an LCA.

(2) ISO 14044:

Life Cycle Assessment – Requirements and Guidelines describes the technical requirements for each stage of an LCA, including data collection, data quality, impact assessment methods, and interpretation of results. ISO 14044 provides comprehensive guidance and technical requirements for the implementation of LCI (Life Cycle Inventory), which is a critical phase of LCA. Conducting LCI under the ISO 14044 framework ensures the quality of data and the reliability of the results. Common LCIs include the following:

In summary, LCA provides a comprehensive environmental impact assessment that helps businesses and decision-makers understand various environmental impacts and make informed decisions. LCA covers multiple environmental impact indicators (such as global warming, ozone layer depletion, resource depletion, acidification, and ecotoxicity), while the carbon footprint specifically focuses on the global warming effect.

2. Product Carbon Footprint System Boundary Setting:

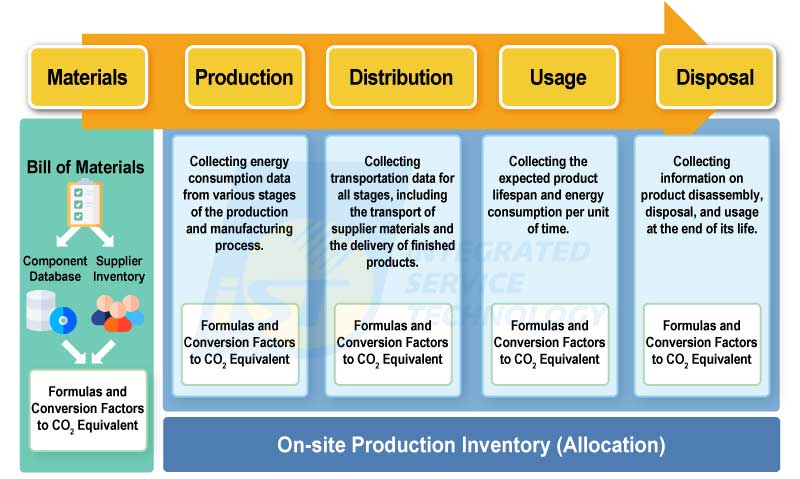

Setting the boundary for product carbon footprint accounting is a critical step in accurately quantifying the carbon footprint. This process involves identifying which life cycle stages, activities, and emission sources should be included in the carbon footprint calculation, and driving related emission reduction measures accordingly. A life cycle-based product carbon footprint typically covers the following key stages:

- Raw Materials: Extraction and processing of raw materials for production purposes from natural resources.

- Production: The process of manufacturing and assembling the product.

- Distribution: The process of transporting the product from the production site to the point of consumption.

- Usage: The stage during the product’s operational life.

- Disposal: The handling of the product at the end of its life, including recycling, reuse, or disposal.

After completing the life cycle definition, it is necessary to further define the system boundaries of the product, including which processes and activities should be included in the scope of assessment. For example, in the case of product packaging materials, the boundary should cover the production of the packaging, energy consumption during the manufacturing process, and the disposal of waste packaging, and other relevant stages. This allows for subsequent data allocation, as shown in the figure below:

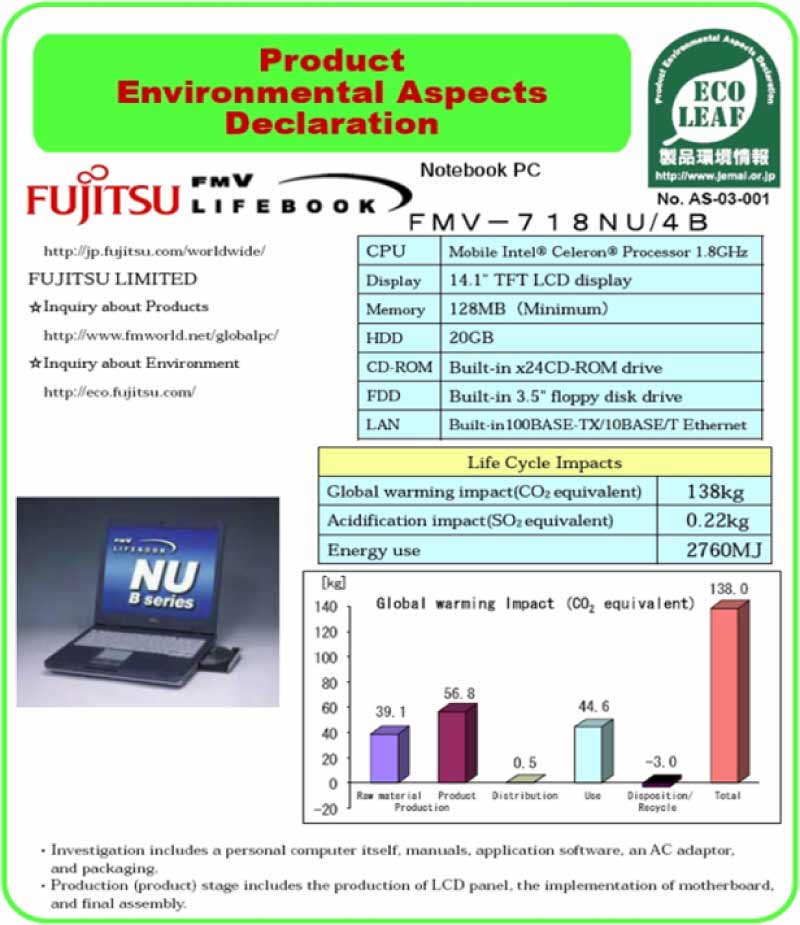

For B2C products, all five stages mentioned above will be covered, while B2B products will only include the first two stages. The figure below shows an example of the carbon footprint for a B2C product.

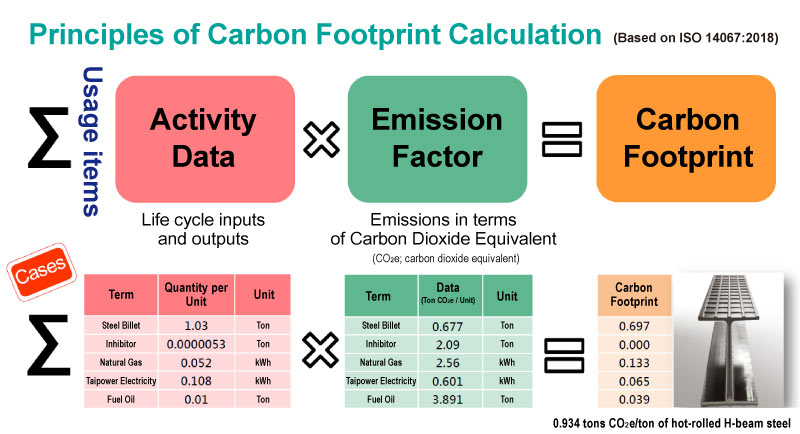

3. Quantifying Product Carbon Footprint: Based on ISO 14067 Requirements and Guidelines for Product Carbon Footprint Quantification

ISO 14067 provides detailed guidelines on how to quantify the carbon footprint of a product. The calculation of a product’s carbon footprint is based on “activity data” and “emission factors”. The figure below shows a related example.

(1) How to Collect Activity Data

Based on different life cycle stages, the details are as follows:

- Raw Material Stage

- Raw material usage (including auxiliary materials and packaging materials): Quantity and weight of each raw material.

- Emissions from raw material manufacturing: Includes greenhouse gas emissions from extraction and processing of natural resources.

- Transportation data: Distance and transportation method (e.g., freight, shipping) from extraction site to processing plant.

- Production Stage

- Energy consumption: Amount of energy used during production, including electricity and fuel (e.g., natural gas, gasoline, diesel).

- Manufacturing process emissions: Greenhouse gases directly emitted during production (e.g., emissions from chemical reactions).

- Waste management: Treatment of solid waste, wastewater, and exhaust gases generated during production, including burning, decomposition, and other disposal methods.

- Distribution Stage

- Transportation distance and method: Distance and mode of transportation from production site to consumer location.

- Energy consumption of transportation vehicles: Fuel consumption and type used by transportation vehicles during the shipping process.

- d. Usage Stage

- Energy consumption during use: Energy consumed by the product during its use (e.g., electricity for home appliances, fuel for vehicles).

- e. Disposal Stage

- Waste treatment method: Different treatment methods (e.g., incineration, landfill) for product disposal at the end of its life, along with corresponding treatment amounts.

(2) Collecting and Applying Emission Factors

Emission factors (EF) are used to convert activity data (such as energy consumption and material usage) into greenhouse gas emissions. ISO 14067 provides guidelines for quantifying product carbon footprints, helping companies effectively collect and apply emission factors. Below are the steps and recommendations for collecting and using emission factors:

- Selecting Emission Factor Sources

- Official Databases: Use standardized emission factors from government and international organizations, such as the United States Environmental Protection Agency (EPA) Emission Factor Database, European Environment Agency (EEA) Emission Factors, International Energy Agency (IEA) energy data, and the Taiwan Carbon Footprint Database.

- Primary Data from Suppliers: Site Specific Data directly collected by suppliers through their own assessments.

- Individual Commercial Data: Use commercially available individual databases and tools, such as Ecoinvent (Simapro) and GaBi.

- Evaluating and Selecting Emission Factors

- Geographical Relevance: Ensure emission factors and use of the product are relevant to the geographic location of production. For example, emission factors for electricity production can vary significantly between countries or regions.

- Temporal Relevance: Use the most up-to-date emission factor data, as technological advancements can impact emissions.

- Applying Emission Factors

- Standardize Calculation Processes: Establish standardized calculation processes for applying emission factors when calculating product carbon footprints to ensure consistency and comparability.

- Leverage Software Tools: Use specialized LCA software tools, such as SimaPro and GaBi, to manage and apply emission factors.

- Data Integration: Integrate emission factors into the product carbon footprint calculation formula, combining them with activity data (e.g., energy use, material consumption) to calculate the total greenhouse gas emissions.

- Raw Material Stage

4. Ensuring the Quality of Carbon Footprint Quantification Data

ISO 14067 sets clear requirements for data quality management to ensure the accuracy and reliability of product carbon footprint quantification. Below are the key data quality management requirements outlined in ISO 14067:

- Data Quality Evaluation Indicators

- Representativeness: Data should reflect the real situation, including relevance to geographical and temporal scope.

- Consistency: Consistent methods and assumptions should be used to collect and process data, ensuring comparability between different data sets.

- Reliability: Data should come from credible sources and be properly verified.

- Accuracy: Data should be as accurate as possible, minimizing errors.

- Completeness: Data should include significant emissions from all life cycle stages to ensure the comprehensiveness of the carbon footprint calculation.

- Traceability: Data sources and processing methods should be traceable to the original records for review and verification.

- Managing Data Quality

- Internal Audits: Conduct regular internal audits to assess data quality and ensure accuracy and reliability.

- External Verification: When necessary, perform external verification to ensure the credibility of the data and the carbon footprint calculation results.

- Conducting Data Sensitivity Analysis

- Sensitivity analysis of the carbon footprint is an important step to ensure the reliability and accuracy of the calculation results. It helps identify and understand the impact of different parameters on the carbon footprint data, allowing decision-makers to further optimize the product’s environmental performance.

- The process involves identifying all major parameters used in the carbon footprint calculation (e.g., energy consumption, material usage, emission factors). Select variables with significant influence on the results or those with high uncertainty for analysis.

- The analysis can be performed using single-factor analysis (adjust each variable one by one while keeping others constant, and calculate and record the carbon footprint results after each adjustment) or multi-factor analysis (simultaneously adjust multiple variables to assess the interactions between them and their combined effect on the carbon footprint results).

- Based on the sensitivity analysis results, propose specific improvement measures, such as replacing high-carbon footprint materials or improving energy usage efficiency.

- Continuous Improvement and Updates.

- Continuous Improvement: Regularly review and improve data collection and processing procedures, adopting the latest technologies and methods to enhance data quality.

- Data Updates: Periodically update data based on the latest technologies, methods, and emission factors to ensure the accuracy of carbon footprint calculations.

ISO 14067’s data quality management requirements cover all aspects of data collection, evaluation, control, and improvement. By adhering to these requirements, companies can ensure that the data used for calculating their product carbon footprint is accurate, reliable, and transparent, thereby enhancing the credibility and scientific validity of their carbon footprint reports.

- Data Quality Evaluation Indicators

5. Carbon Footprint and Environmental Product Declaration (EPD):

The product carbon footprint and the Environmental Product Declaration (EPD) are two related but distinct concepts that both provide information about a product’s environmental impact, helping businesses and consumers make more sustainable choices.

The EPD is a technical document prepared in accordance with the ISO 14025 international standard, offering information on the environmental impacts of a product throughout its life cycle. EPDs are based on life cycle assessment (LCA) data and can be certified by third parties. The product carbon footprint is often a part of the EPD, particularly in relation to global warming potential (GWP). While the EPD includes a broader range of environmental impact data, the carbon footprint focuses on greenhouse gas emissions. Examples are as follows:The product carbon footprint and the Environmental Product Declaration (EPD) are both important tools for assessing and communicating the environmental impact of products. The carbon footprint focuses on greenhouse gas emissions, while the EPD provides comprehensive environmental impact information. When used together, they help businesses and consumers make more sustainable choices, promoting environmental protection and sustainable development. In addition to ISO 14067, the Greenhouse Gas (GHG) Protocol also provides detailed guidelines and methodologies for calculating product carbon footprints.

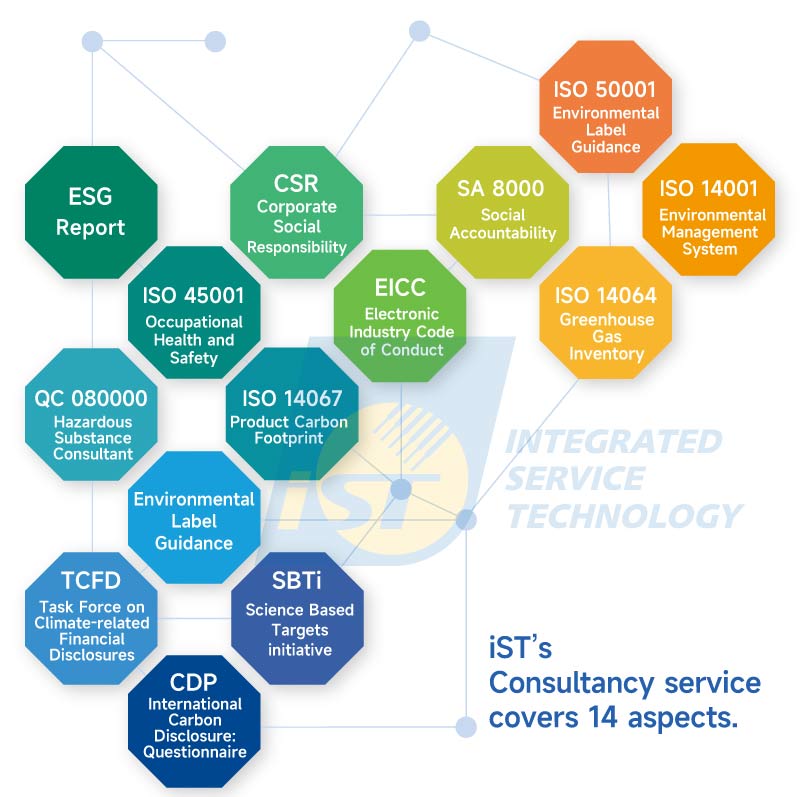

With extensive experience assisting hundreds of companies, iST has helped clients achieve numerous value-added certifications, enabling them to successfully enter international supply chains. Our clients include globally renowned leaders in contract manufacturing, semiconductor equipment manufacturers, IC design companies, optoelectronics, electronic component manufacturers, electronic system integrators, and traditional industries listed on Taiwan’s stock exchange. In ESG consulting, iST can also assist with greenhouse gas inventory, product carbon footprint, climate-related financial disclosures (TCFD), Science Based Targets Initiative (SBTi), and ISO 50001 relevant energy management and conservation services (Figure 8).

Since 2011, iST has accumulated extensive experience in assisting leading domestic companies in implementing carbon footprints through the Ministry of Economic Affairs’ “Product Carbon Footprint and Energy-Saving and Carbon-Reduction Information Service Platform and Tool Development Project.” We believe that the proportion of carbon emissions from suppliers and opportunities for reduction are key to showcasing “product environmental performance,” which is one of the main purposes of introducing carbon footprints.

As a result, on-site supplier assessments are crucial, especially for local suppliers that contribute significantly to emissions. iST has defined around 30 key indicators, enabling companies to use this data to collaborate with suppliers in building a carbon-reduction value chain.

If you would like to learn more about ESG and product carbon footprint consulting, please feel free to contact Mr. Lin at +886-3-579-9909 ext. 8807 or Ms. Hsu at ext. 8803 | E-mail: web_isd@istgroup.com .