Issued Date:2024/8/15 space environmental testing

Issued By:iST

By 2040, the global space economy is poised to shatter the $1 trillion mark, enticing a flurry of electronics manufacturers into the cosmic marketplace. However, when confronted with the rigorous challenges of rocket launches and the harsh confines of space, how does one orchestrate ground-based simulations to ensure the flawless operation of their products in orbit?

space environmental testing

Since the launch of the first artificial satellite in 1957, nearly ten thousand satellites are now orbiting in space, and this number continues to grow. Satellites have become an integral part of our daily lives, providing services such as map navigation and live broadcasts. Additionally, the “Starlink” satellite communication network was utilized during the Russia-Ukraine war, and Taiwan employed low-orbit satellite technology for the first time to assist with communications in disaster-stricken areas during the Hualien earthquake on April 3rd. Therefore, the development of satellite technology not only serves civilian purposes but also has significant national security implications.

From 2019 to 2029, our country will invest over NT$40 billion in the third phase of the “National Space Technology Development Long-term Plan.” This investment is focused on the development of low-orbit communication satellites, the planning of a national launch site, and talent cultivation. The Industrial Technology Research Institute (ITRI) estimates that by 2030, 1,700 satellites will be launched annually worldwide, creating an output value of at least $400 billion. According to the Satellite Industry Association (SIA) in the United States, the global space economy is expected to exceed $1 trillion by 2040, with the satellite industry accounting for up to 88% of this, reaching $925.2 billion.

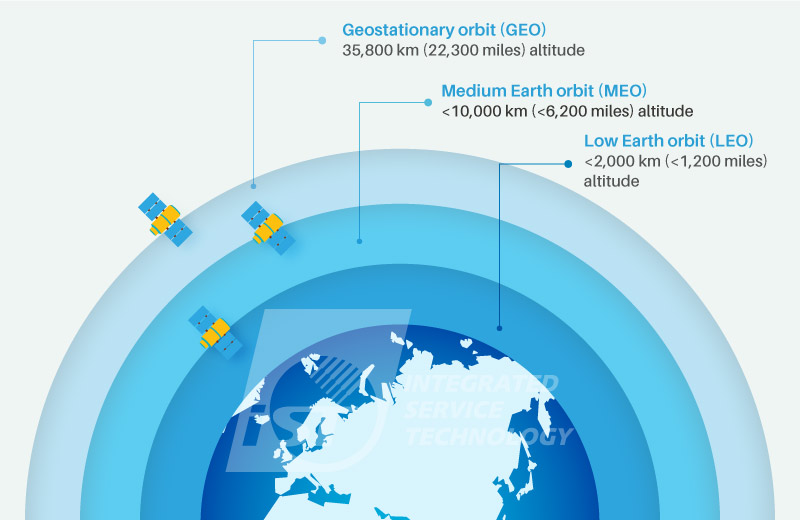

Satellites can be classified by their orbital altitudes into Low Earth Orbit (LEO, <2,000 km), Medium Earth Orbit (MEO, <10,000 km), and Geostationary Orbit (GEO, ~35,800 km) (Figure 1). Their weights vary from a few kilograms to several hundred kilograms. In recent years, SpaceX’s Starlink LEO communication satellites have been commercialized, initiating a new space economy model. Additionally, CubeSats, which have relatively low manufacturing costs, have become a popular entry point for satellite technology research. The satellite industry chain is becoming increasingly mature, and the reduction in satellite launch and manufacturing costs is creating significant business opportunities in space. This, in turn, increases the demand for electronic components, encouraging many companies to gear up for entering the space market.

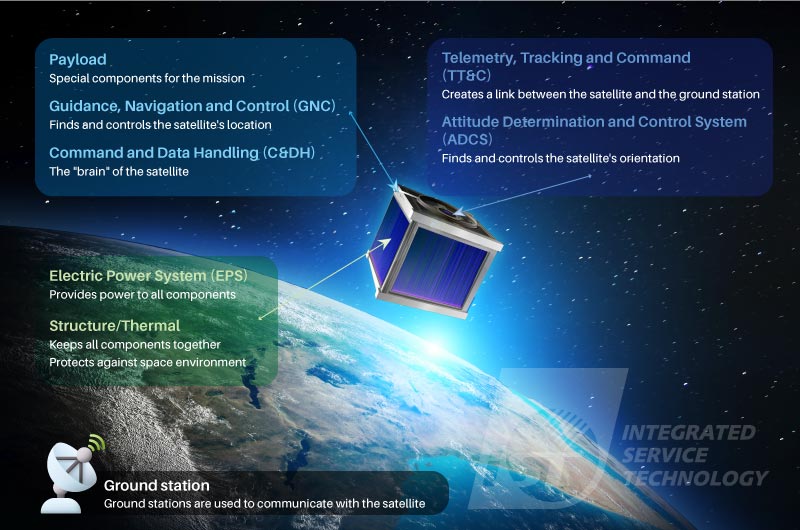

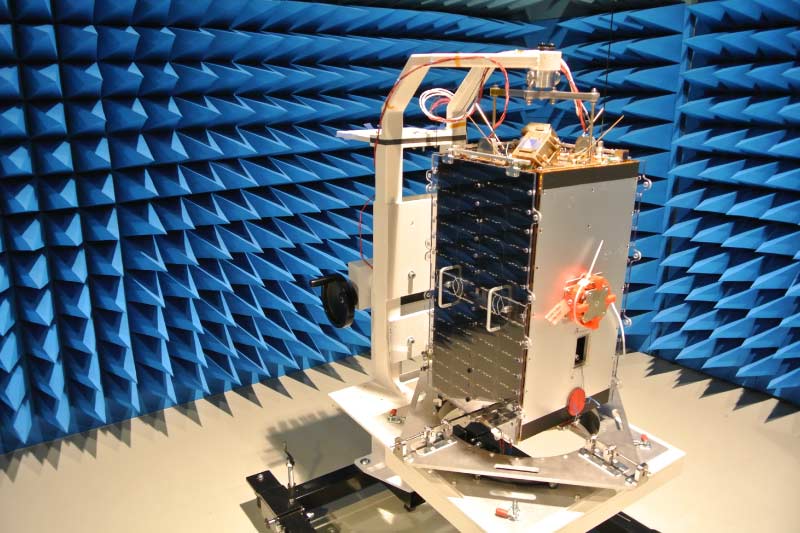

Satellites are composed of several integrated subsystems, including attitude control, power, thermal control, communication, propulsion, and payload, among others (Figure 2). For example, a Remote Sensing Satellite, which functions to capture images while orbiting the Earth, relies on the attitude control subsystem to keep the camera pointed towards the Earth. The imaging sensor serves as the payload that captures the images. The power subsystem is responsible for power storage and management, and the communication subsystem transmits the images back to Earth. Inside the satellite, various familiar electronic components are utilized.

Traditional space-grade electronic components come with a hefty price tag, and some parts are challenging to acquire due to various countries’ regulatory policies. In contrast, Commercial Off-The-Shelf (COTS) electronic components, such as those used in computers, mobile phones, and automobiles, are relatively affordable, perform well, and are readily available. In recent years, utilizing COTS components for space missions has become a popular trend.

What verification tests are required for COTS electronic components to be deployed in space? This episode of iST’s Classroom will explain the challenges and validation testing methods that COTS components face when transitioning to space applications, covering the rocket launch environment and the space environment.

space environmental testing

space environmental testing

1. 3.2.1 Launch! The Impact of Rocket Launch on Electronic Components

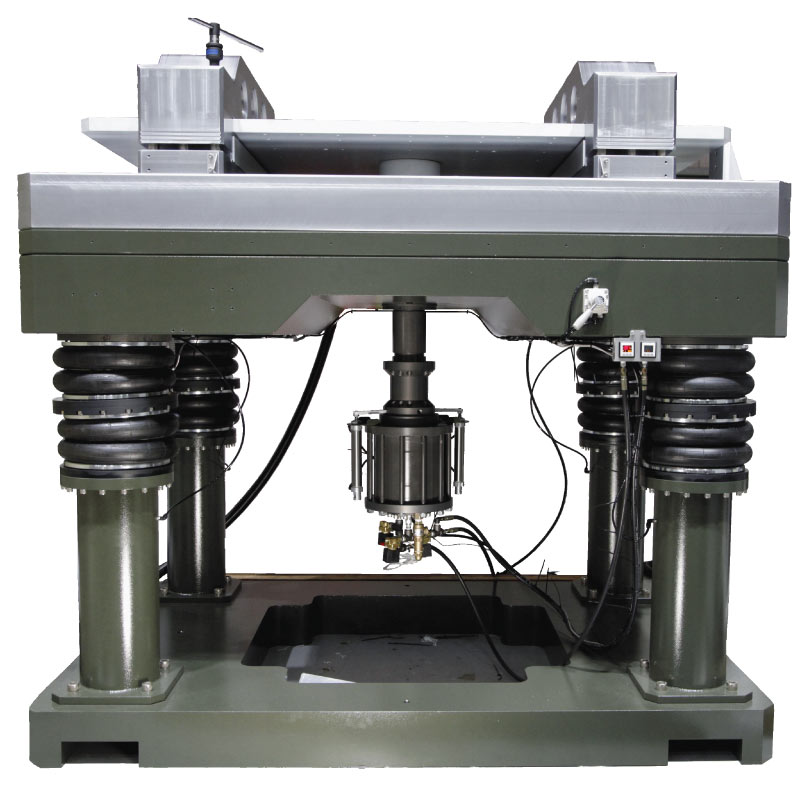

(1)Vibration Testing

When manufacturing and assembling satellites on the ground, factors such as temperature, humidity, and dust contamination must be considered. Once assembled, the satellite is launched into space aboard a rocket, initially enduring the intense vibrations of the rocket launch. Vibration testing machines can simulate rocket launch conditions on the ground, performing vibration tests in both vertical and horizontal directions. Different rockets have varying vibration levels. For example, the vibration test parameters for the SpaceX Falcon Heavy rocket (Figure 3) include vibration frequencies ranging from 10 to 2,000 times per second and gravitational accelerations up to several tens of times. Vibration testing (Figure 4) can be used to verify that the satellite or its electronic components can still function normally after the launch process.

(2)Acoustic Testing

The rocket launch process also generates acoustic noise, which can particularly affect large and thin components such as solar panels and antenna panels. Acoustic noise may cause these components to crack, suffer structural damage, or malfunction. An acoustic chamber is used to simulate the acoustic noise generated by the rocket. During testing, liquid nitrogen is vaporized, causing its volume to expand hundreds of times instantly, producing immense pressure. This pressure is then converted into sound waves via speakers, which are directed into the acoustic chamber to test the satellite or its components (Figure 5).

(3) Shock Testing

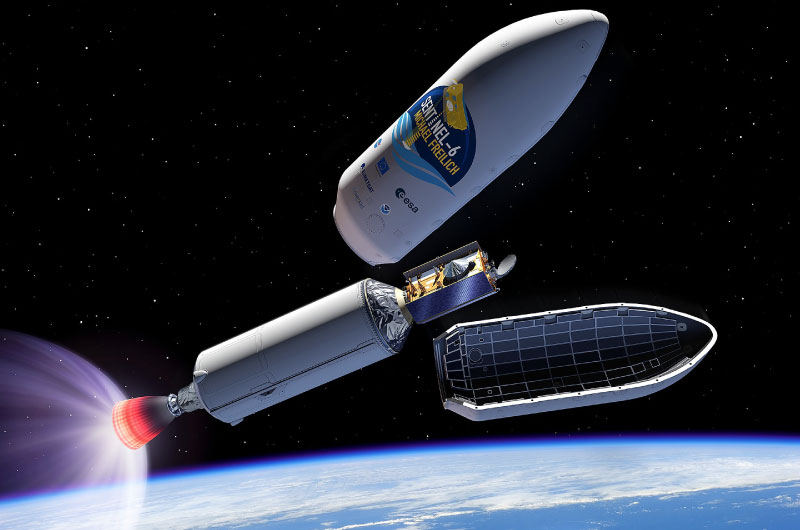

When the rocket leaves the ground and reaches a certain altitude, the rocket stages begin to separate one by one, and then the fairing opens to release the satellite into orbit (Figure 6). These processes generate shocks, which pose severe tests for the solder joints, silicon chips, and other brittle materials of the satellite’s internal components. Therefore, shock testing must also be conducted on the ground (Figure 7) to understand the satellite and its electronic components’ tolerance to significant shocks.

(4)Electromagnetic Compatibility Testing (EMC)

Furthermore, due to the concentration of various electronic components within the confined space of the rocket, electromagnetic interference between the satellite and the rocket may affect the mission. Therefore, before launch, the satellite must undergo Electromagnetic Compatibility Testing (EMC) (Figure 8) to ensure that the electronic components used in the satellite do not interfere with each other or with the rocket.

2. How Does the Space Environment Affect Electronic Components?

(1) Thermal Vacuum Cycling Test

Low Earth Orbit (LEO) satellites travel at a speed of seven kilometers per second, completing an orbit around the Earth every ninety minutes. As these satellites orbit in a vacuum environment, they face significant temperature challenges. When directly exposed to sunlight, the satellite’s temperature can soar to 120 degrees Celsius, whereas when it is away from the sun, the temperature can plummet to -120 degrees Celsius. Moreover, the vacuum environment can cause electronic components to overheat due to poor heat dissipation. The low pressure of the vacuum can also lead to material decomposition, cavity leaks, or outgassing, which results in contamination.

The Thermal Vacuum Cycling Test (Figure 9) can simulate the vacuum conditions and temperature fluctuations of the space environment. During the test, the satellite or electronic components are placed in a vacuum chamber with extremely low pressure. The equipment then uses radiation and conduction methods to raise and lower the temperature of the satellite or electronic components to mimic solar exposure. During this process, the satellite or electronic components are powered on and operating, with their functionality being continuously monitored to ensure they perform correctly. Thermal vacuum cycling tests usually last for a week or even longer, and they are a common cause of failures in satellites and electronic components.

(2) Radiation Testing

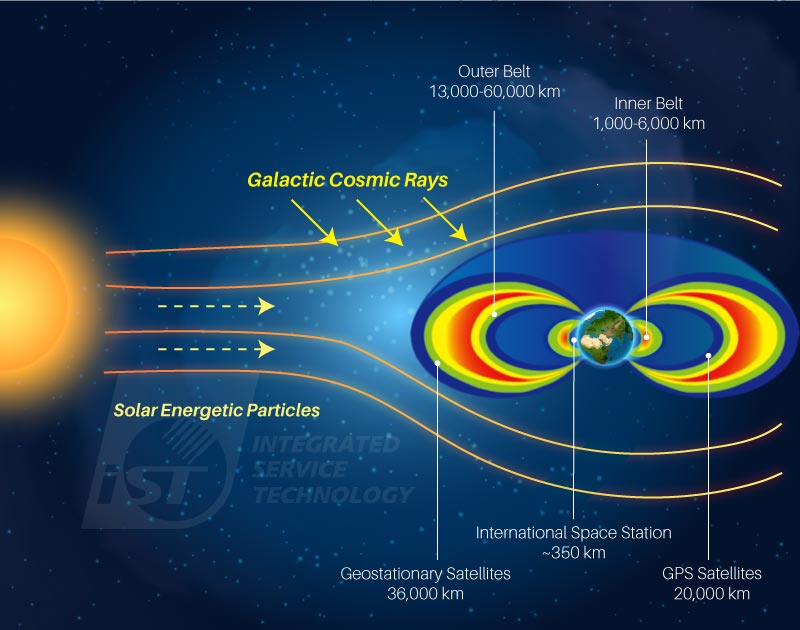

In the space environment, electronic components are directly exposed to radiation without the protective shield of the Earth’s atmosphere. In Earth’s orbit, the radiation environment includes the Van Allen Belts, Galactic Cosmic Rays (GCR), and Solar Energetic Particles (SEP) (Figure 10). These radiation environments are filled with a high density of electrons, protons, and a small number of heavy ions, which can cause data upsets, system crashes, and even permanent failures if they strike satellite electronic components (Figure 11). The operational lifespan of satellites in orbit can vary from a few months to several decades. The longer a satellite remains in orbit, the greater its susceptibility to radiation-induced effects.

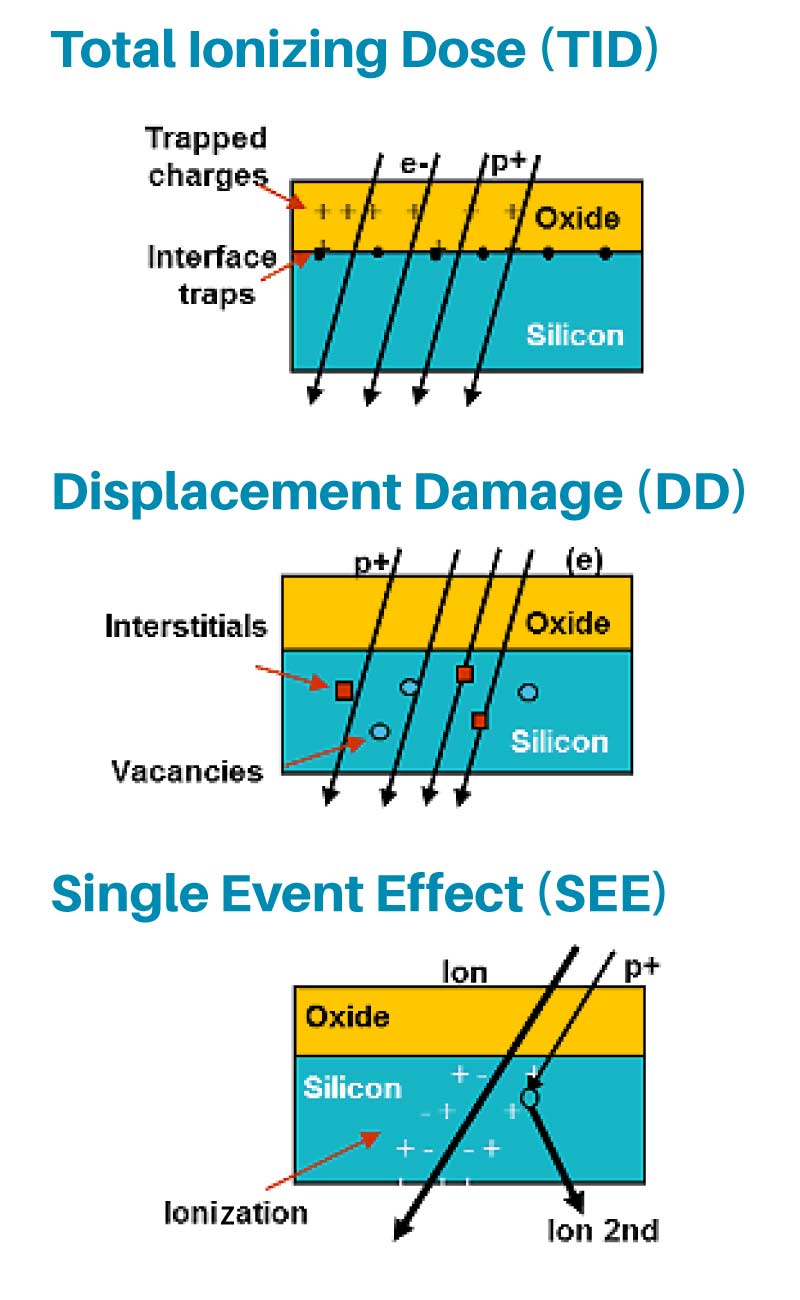

The effects of radiation on electronic components can be categorized into three main types:

1. Total Ionizing Dose Effect,TID

In the space environment, electronic components accumulate significant amounts of proton and electron radiation over time, which is the primary cause of Total Ionizing Dose (TID) effects. TID can lead to a gradual drift in the Threshold Voltage of MOS transistors, resulting in an increase in component leakage current. When leakage current becomes severe, it can lead to component burnout. Satellites can be likened to large-scale wireless mobile devices, relying on solar power storage. Power is precious in space, and if many electronic components within the satellite experience leakage current, it can lead to insufficient power, causing loss of communication or loss of control.2. Displacement Damage,DD

Protons can induce another type of non-radiation effect on electronic components known as displacement damage (DD). This effect involves the long-term accumulation of protons causing physical damage to the semiconductor material. Protons can displace silicon atoms from the crystal lattice within semiconductor components, creating defects in the semiconductor material. This leads to an increase in component leakage current over time. Photonic components are particularly sensitive to DD effects, such as image sensing devices, where DD can degrade image quality. Additionally, DD can reduce the efficiency of solar cells used in satellites.3. Single Event Effect,SEE

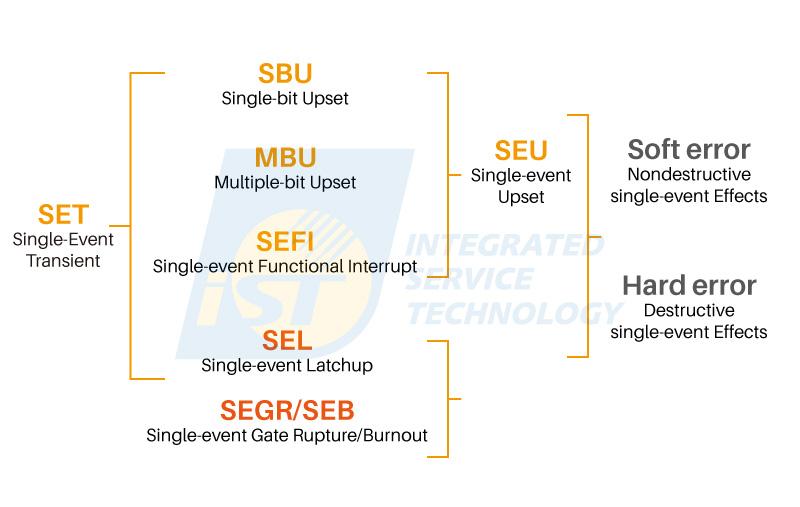

TID and DD can be likened to chronic conditions, resulting from the long-term accumulation of proton and electron interactions on electronic components in orbit, leading to leakage effects. On the other hand, Single Event Effects (SEE) (Figure 12) can be seen as acute symptoms that occur randomly and are difficult to predict. Both protons and heavy ions can induce SEE in electronic components, with heavy ions being more likely to trigger SEE. While heavy ions are less common in space environments, their impact can be severe, potentially causing electronic components to malfunction or fail.

SEE-induced failures can be categorized into two main types: Soft Errors and Hard Errors. Soft Errors manifest as data corruption, system crashes, or abnormal functionality, which can typically be recovered by resetting the circuit. However, if electronic components are highly sensitive to radiation, frequent system crashes can affect mission execution, necessitating radiation testing to evaluate their Event Rate. Hard Errors, on the other hand, are permanent failures. For instance, heavy ions are prone to induce phenomena like Single Event Latch-Up (SEL), where components may burn out due to high currents if there is no corresponding mechanism in place. Therefore, SEL (Single Event Latch-Up) is one of the most critical indicators of radiation tolerance for space electronic components.

The space environment encompasses particles of various energies, including protons, electrons, and heavy ions. Higher-energy particles can penetrate thicker materials or outer shells. Low-energy particles can be blocked by the satellite’s outer shell (typically aluminum), but since satellite launch costs are mainly determined by weight, the thickness of the outer shell is limited (usually a few millimeters thick aluminum). On the other hand, high-energy particles can penetrate the satellite’s outer shell, affecting the operation of electronic components. Therefore, electronic components used in space environments are inevitably affected by radiation and must undergo radiation testing to assess their characteristics before being sent into space. COTS electronic components typically possess some level of radiation resistance, but their radiation tolerance must be evaluated through testing to ensure suitability for space mission requirements (Figure 13).

3.The Final Milestone for Electronics to Ascend to Space Components

COTS electronic components must undergo “launch environment testing” before being sent into space, including simulating the vibrations, acoustic noise, shocks, electromagnetic compatibility testing, as well as thermal vacuum cycling and radiation testing in space (more testing items are not listed here one by one). After passing these tests, it is even more important to obtain “flight heritage”. By launching the product into space and successfully executing various missions, the more flight heritage obtained, the higher the value of the product. The space industry attaches great importance to flight heritage, which serves as the best guarantee for the product.

iST is Asia’s most comprehensive third-party laboratory for space environment testing. In 2019, iST collaborated with the Taiwan Space Agency (TASA) to promote the development of Taiwan’s space industry. Since joining the Taiwan Space Radiation Environment Testing Alliance in 2021, iST has completed radiation tests for various electronic components, including analog, digital, memory, RF, and power devices. iST continues to enhance its space environment verification and testing capabilities, offering one-stop services. Through professional specialization, iST assists domestic and international manufacturers in conducting space environment tests, allowing them to focus more on product design and manufacturing.

Thank you for your continued support of iST. If you have further questions or need assistance, please feel free to contact Mr. Jack at +886-3-579-9909 ext. 8800 or via Email at iST_Space@istgroup.com ; marketing_tw@istgroup.com