Issued Date:2025/11/6 Rubber Socket PCR

Issued By:iST

In QFN (Quad Flat No-Lead) package final testing, engineers often face a recurring bottleneck: the conventional PCR (Pressure Conductive Silicone Rubber) sockets typically last only 20K–30K cycles, leading to frequent maintenance, production downtime, and soaring testing costs.

3D Surface

Rubber

Rubber

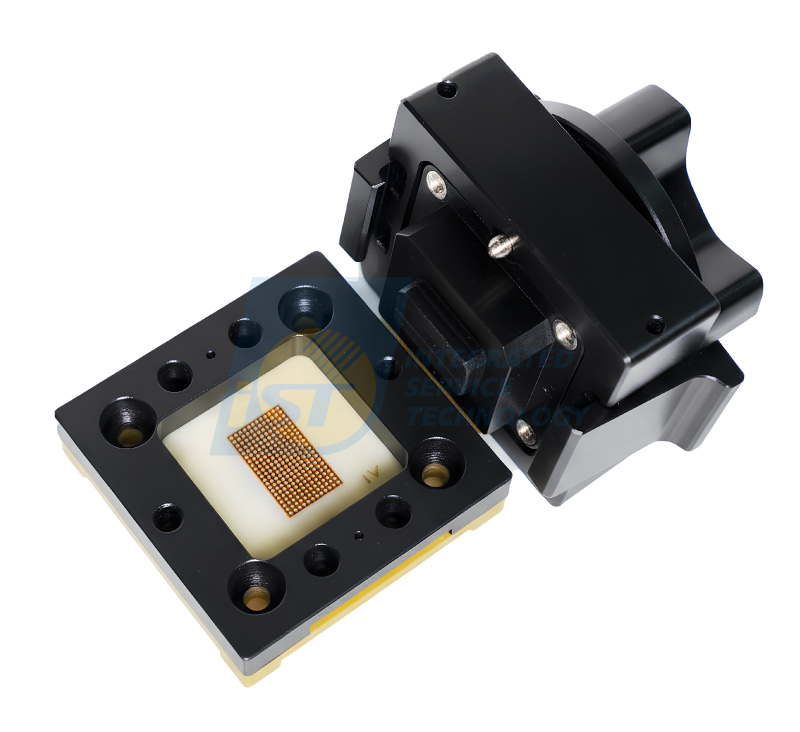

1. iST Rubber Socket (PCR) : 5× Durability Breakthrough for QFN FT

iST introduces its next-generation QFN Rubber Socket (PCR), featuring an extended service life of up to 150K cycles—over 5× that of conventional products!

Even under 125°C high-temperature conditions, it maintains stable conductivity through 100K+ mating cycles, delivering exceptional durability and reliability.

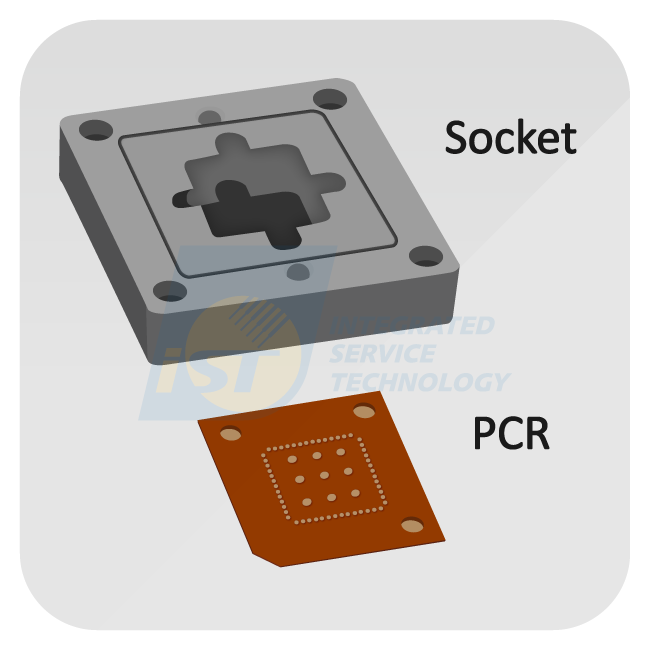

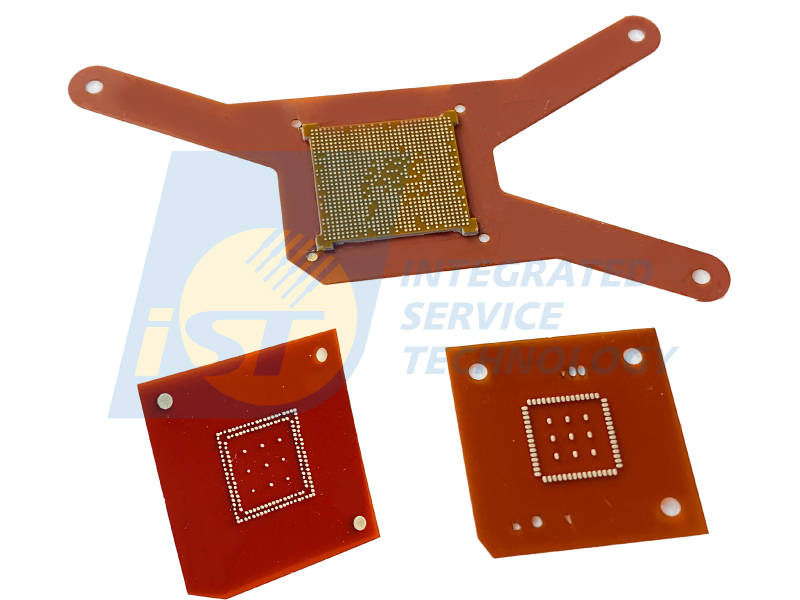

2. What Is Rubber Socket (PCR) — and Why Is It Superior to Pogo Pins?

Rubber Socket / PCR (Pressure Conductive Silicone Rubber) is a material in which conductive particles are dispersed within silicone rubber:

- When pressure is applied, it forms a stable conductive path — without the need for high-temperature soldering.

- Compared with traditional pogo pins, PCR offers superior signal integrity, contact indentation control, and low-temperature performance, effectively reducing the risk of damaging chip contact balls during testing.

- It supports applications such as Burn-in Boards, Load Boards, and System-Level Tests, making it the ideal interconnect solution for advanced package testing.

3. Key Advantages of iST’s Rubber Socket (PCR) Technology

- Extended Lifetime: Over 100K mating cycles at 85°C, with QFN socket proven life reaching 150K cycles (under recommended compression depth).

- Low Contact Resistance: Initial resistance below 50 mΩ.

- High-Speed & High-Frequency Ready: Bandwidth up to 40 GHz, ideal for high-speed signal validation.

- Lead-Protective Design: Gentle test force of 15–50 gf prevents damage to fragile IC pins.

- Flexible Structure: Compatible with ≥0.3 mm pitch and thickness 0.5–1.2 mm, adaptable to various test socket designs.

- Excellent FSR Characteristics: Stable conduction at low pressure, smooth and controllable impedance curve, and consistent test data even under varying mating conditions.

4. A Robust and Reliable QFN FT Test Solution

By adopting iST’s QFN Rubber Socket (PCR), you can drastically reduce replacement frequency and maintenance costs, enhance mass-production testing efficiency, and ensure consistent test data integrity.

If you would like to learn more details, feel free to contact Ms. Lin/Aaliyah | Tel:+886-3-5799909#8890 | Email:HWBU_Sales@istgroup.com ; marketing_tw@istgroup.com.