3D X-ray are also ideal for non-destructive inspection over 3D IC, MEMS, and even PCB, PCBA, lithium battery/engineering Plastics…

To keep up with the demand for high-speed transmission, automotive semiconductor chips are growingly packaged in MCM/SiP assembly, instead of BGA…

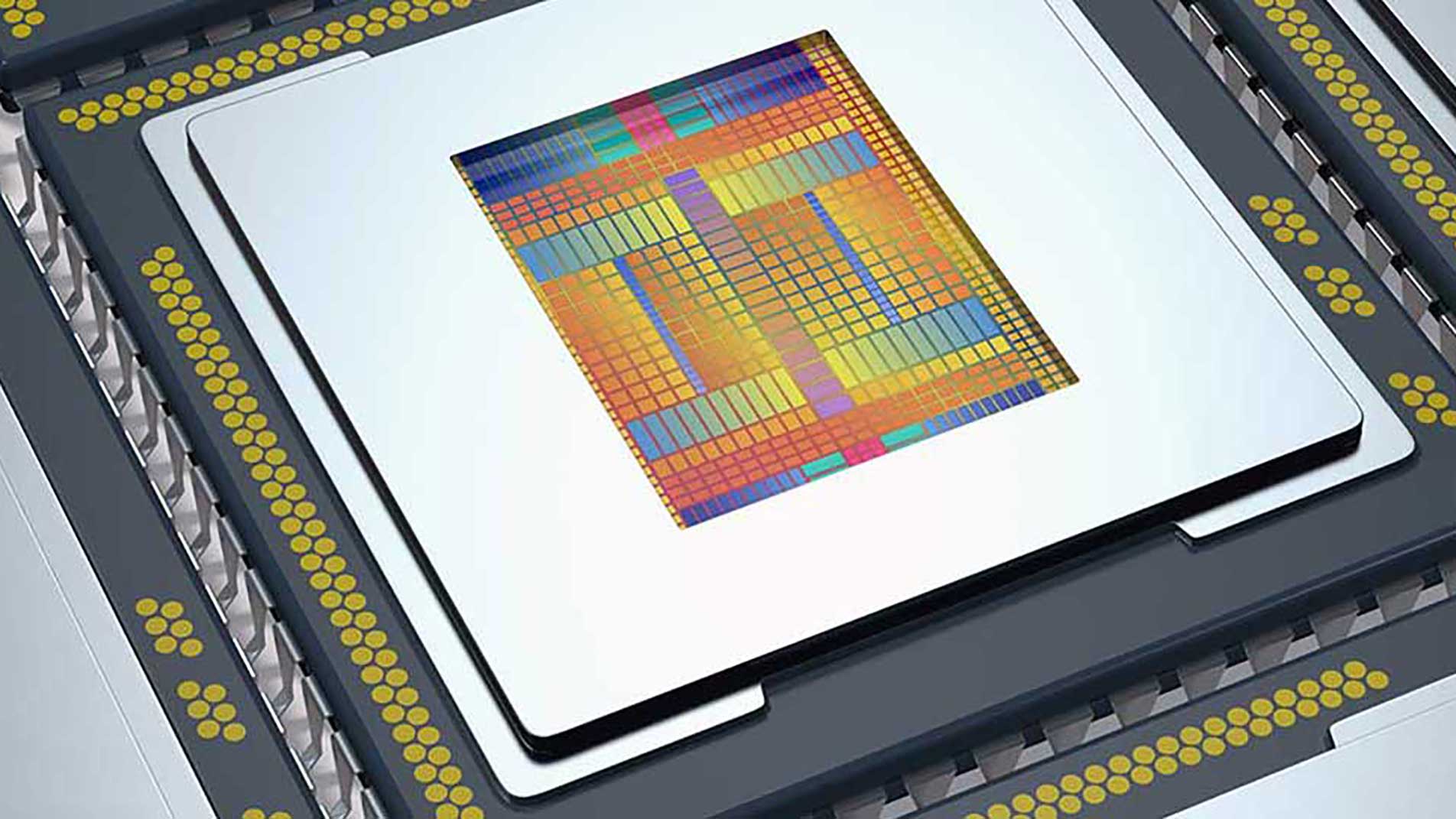

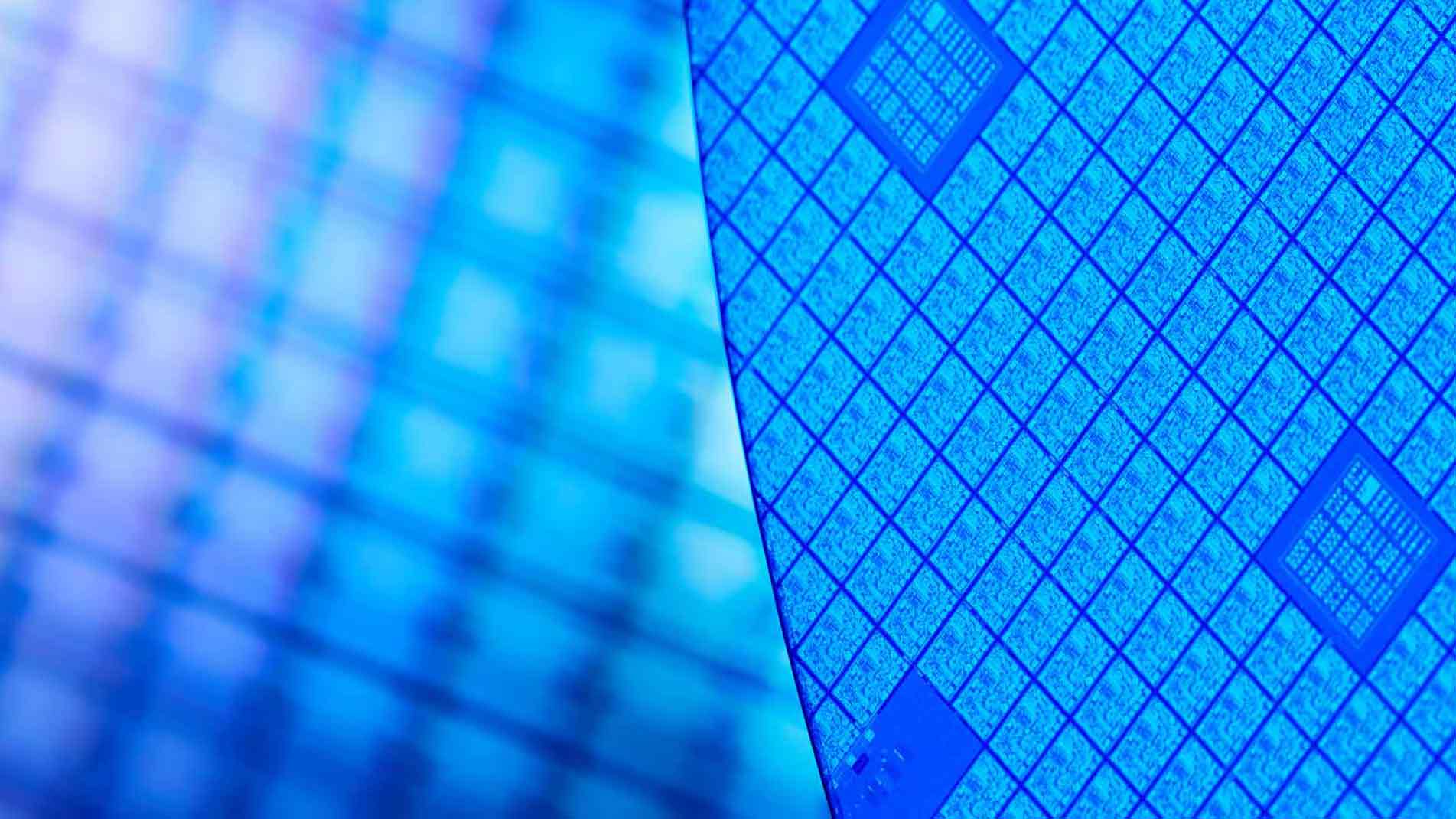

As predicted by Moore’s Law, the IC process is continuously shrinking down to below 16 nm, as most of ICs package types are flip chip packages, backside…

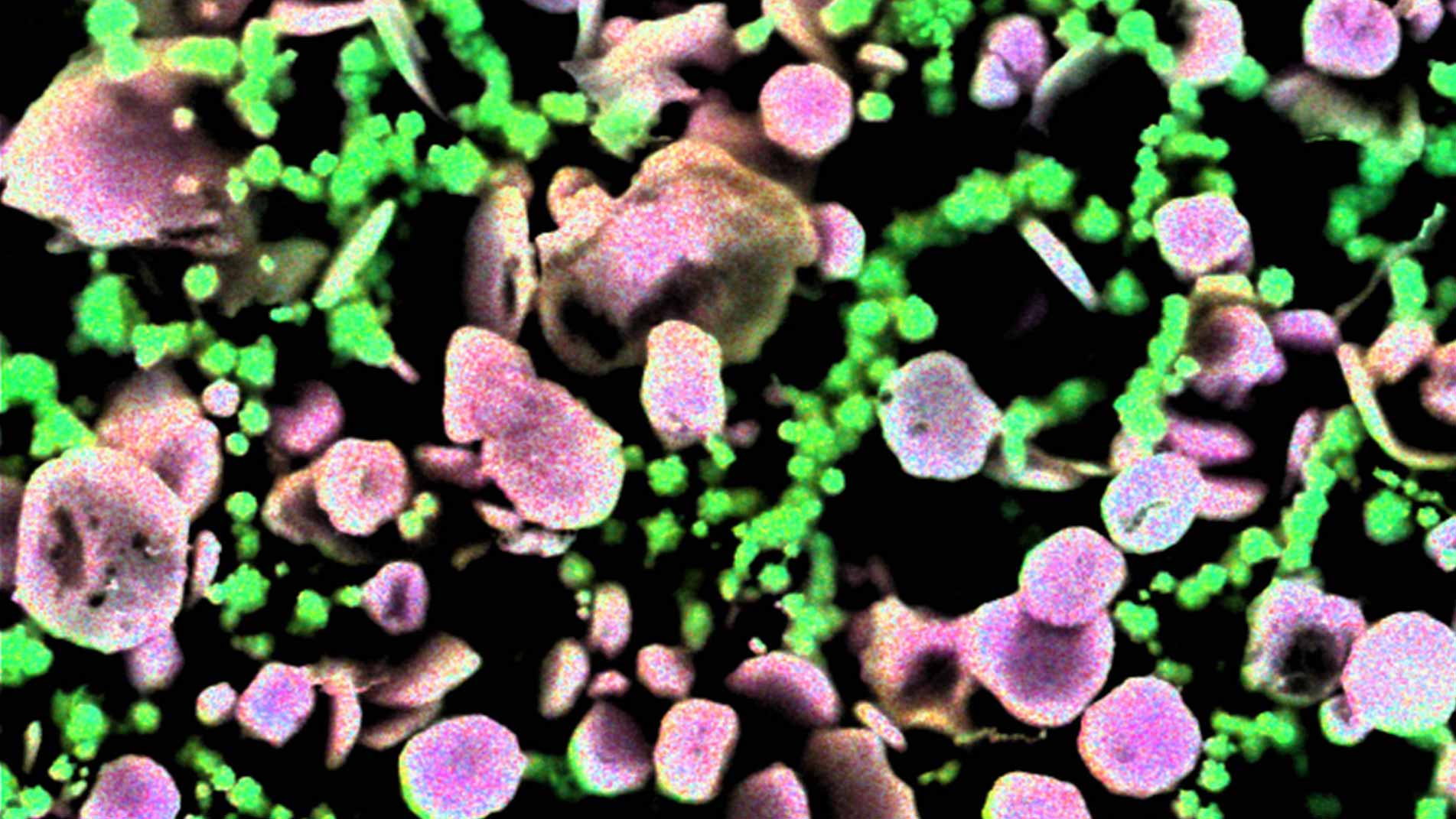

SEM liquid platform is a closed structure which can enclose liquid/volatile materials with the SiN film of several tens of nano thick on the surface of a SEM platform…

Electro-less Plating process has one critical feature: it can grow NiAu or NiPdAu selectively on Al pads with a series of redox reactions instead of…

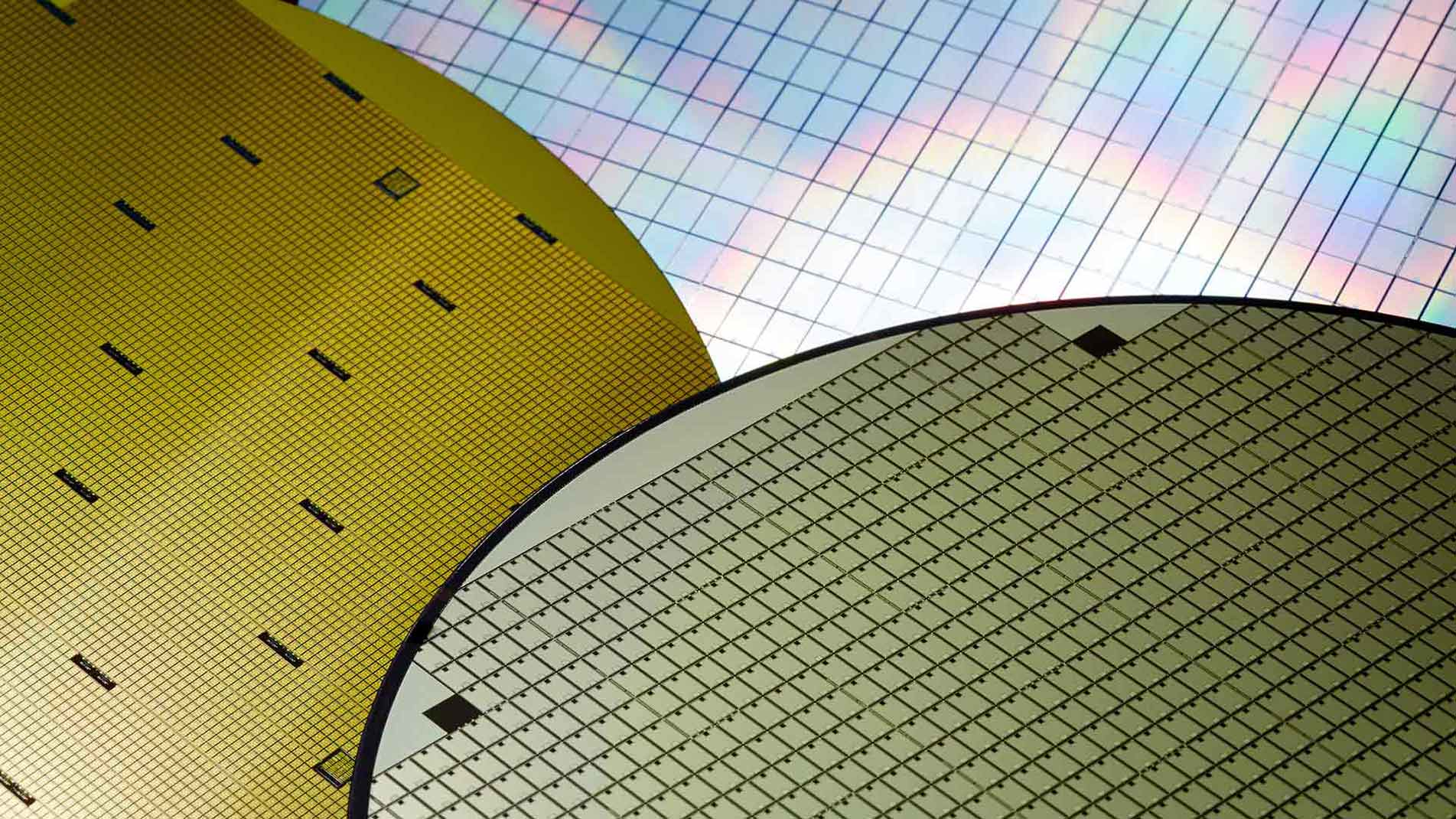

FSM is a critical process for MOSFET wafer thinning. Featuring high switch speed, low input impedance and low power consumption, the MOSFET is…