Issued Date: 2015/1/9

Issued By: RICHTEK & iST

RICHTEK Technology and iST jointly announced cooperation results in inspecting Micro Electro Mechanical Systems (MEMS) today (1/9). Both companies proposed optimal analysis and debugging solutions addressing MEMS G-Sensors actively developed by RICHTEK. Based on the successful cooperation in 2013 on the typical failure analysis flowchart established by iST for the first generation MEMS G-Sensor, the second-round cooperation in 2014 on the 2G MEMS analysis technology has successfully enabled RICHTEK in verifying failure factors in the design phase of the MEMS. This analysis technique has further gained recognition of the International Symposium on Quality Electronic Design (ISQED).

Following the growth of smart products, wearable devices and Internet of Things, the demand of MEMS G-Sensor elements expands gradually. IC Design companies deploy actively to set foot in this market.

“RICHTEK is a leading supplier of MEMS in IC design companies. iST is privileged to have gained trust of RICHTEK for long-term cooperation by verifying failure factors of MEMS G-Sensor, assisting RICHTEK in expediting the process of product design, final design and commoditization,” so says Kim Hsu, Director of Failure Analysis Division, iST.

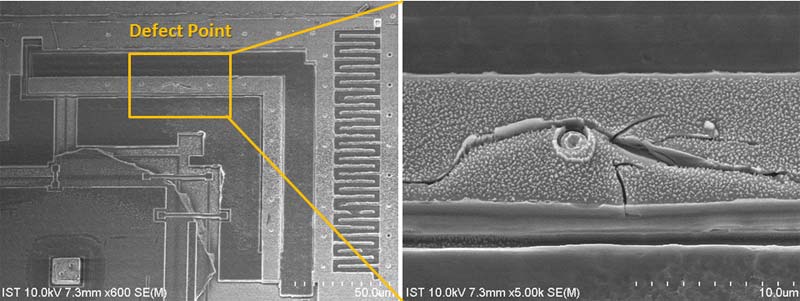

Hsu further notes that, through the 2G MEMS analysis technology, iST has successfully removed the entire mass of the MEMS G-Sensor under a stress free condition and observed damage in the joint beneath the underlying fixed mass. The defect point has been verified consistent to the electronic signal anomaly (see figures below), which is proven the real cause of the failure.

Yi Jing-Yun, Director of QA Division RICHTEK, said, “Both parties specifically developed long-term in-depth cooperation in product reliability and failure analysis. This time, with close collaboration started from the design phase in MEMS G-Sensor of RICHTEK, iST provided plentiful expertise suggestions and solutions and dedicated in establishing optimal market leading MEMS solutions, iST becomes one of the important partner to RICHTEK in the verification of MEMS products.”

About RICHTEK

RICHTEK Technology Corporation is one of the world’s leading analog IC companies. The company consistently delivers inventive power management solutions that improve the performance of consumer electronics, computers, and communications equipment. RICHTEK adds value to end equipment by synthesizing technological innovation, uncompromised quality, and devotion to customer service. Founded in 1998, the Company is headquartered in Taiwan with additional offices in Asia, the U.S., and Europe. RICHTEK is publicly traded on the Taiwan Stock Exchange under the ticker symbol 6286. For more information about RICHTEK and its analog IC solutions, please visit the Company’s Web site atwww.richtek.com。

About Integrated Service Technology

Founded in 1994, iST began its business from IC circuit debugging and modification and gradually expanded its scope of operations to include failure analysis, reliability verification, material analysis, and quality assurance. Through the years, iST has constructed a comprehensive verification and analysis engineering platform, offering full-scope services to the IC engineering industry. iST customers cover the whole spectrum of the electronics industry from IC design to end products.

In response to rising environmental awareness, iST not only focuses on its core services but is also expanding its service offerings based on international trends. iST’s lead-free and halogen-free verification testing, chemical quantitative testing and signal integrity services have all been accredited by multiple international independent third-party organizations including TUV NORD Germany and BSI UK. With increased outsourcing by major international brands, iST now also plays the role of independent quality testing laboratory for OBM outsourcing products and is certified by Dell, Cisco, Delphi, Continental Automotive and Lenovo.

Headquartered in Hsinchu, iST’s pursuit of precision, perfection and efficiency has led it to expand its operations around the world. The iST Group now includes iST Kunshan, iST Shanghai, iST Beijing and iST Shenzhen in China, IC Service in Japan, and an iST laboratory in the US. These are all dedicated to providing customers with prompt, reliable and high-quality technical services in order to grow with the leaders of the world. For more information, please visit the iST website at:www.istgroup.com。