Issued Date: 2013/10/15

Issued By:iST

With the rapid and booming development of advanced technologies, MEMS devices have become the core of intelligent products. As the industry engages in MEMS development, the conventional analytical techniques are unable to identify the true causes of MEMS failure. To address this challenge, the iST Group Taiwan has successfully demonstrated this year the establishment of a standard flow of failure analysis for the MEMS G-sensor. This flow has also been adopted by various companies in practical applications. At present, the iST Group Taiwan is handling the failure analysis and related solutions for up to about 90% of the companies developing the MEMS G-sensor.

The proprietary standard flow of failure analysis for the MEMS G-sensor by iST has also been certified by the well-known ISTFA (International Symposium for Testing and Failure Analysis), becoming the first and the only laboratory with its own MEMS research team in Taiwan.

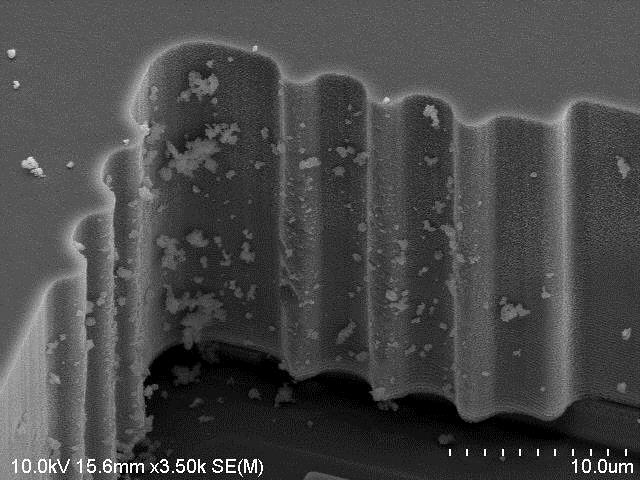

The observations by iST show that the conventional MEMS failure analysis method via De-cap is subject to device contamination due to the lack of structural understanding and control by many companies.

In addition, the iST further points out that damage easily occurs during the process of removal by foreign forces given that the device is a suspended structure. These two issues often cause contamination and stress damage to the devices, creating more failure blind spots instead of identifying the true causes.

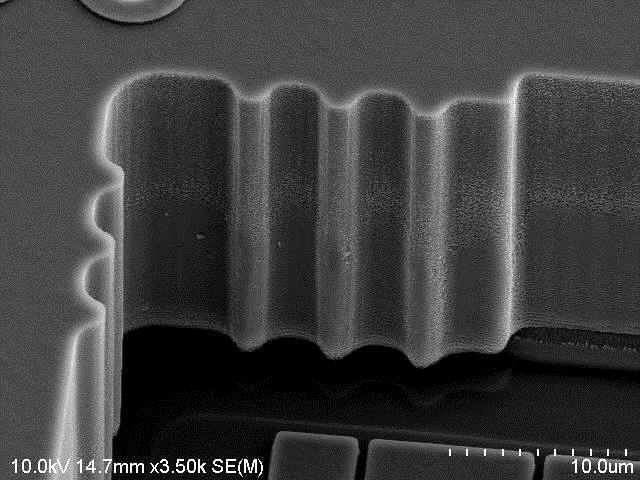

To address this issue, iST successfully developed this year the De-cap MEMS technique that is free of contamination, which combined with a stress-less device removal technique preserves the original structure by non-invasive methods, avoiding false failure causes from mechanical stress and contamination. So far, the technique by iST has effectively helped identify failure causes and implemented improvements accordingly to advance in the existing market for more than 30 companies involved in MEMS design, manufacturing and packaging.

As pointed out by the COO of the iST Group, Jandel Lin, iST started engaging in the research and development of MEMS failure analysis as early as 2007. As he envisioned the potential market demand through a comprehensive layout of failure analysis techniques for emerging products such as MEMS. With the extensive practical experience acquired over the past few years, iST achieved the establishment of the standard flow of MEMS failure analysis.

Jun-An Huang, the technical manager of the iST Group Taiwan, will present this technique on November 6 at the ISTFA in San Jose, California, USA. All the interested colleagues and friends in the industry are cordially welcome to join us in this event.

If you have any further business inquiries, please contact Mr. Brian Wang at +886-3-579-9909 ext. 8886

About the iST Group

Founded in 1994, iST began its business from IC circuit debugging and modification and gradually expanded its scope of operations to include failure analysis, reliability verification, material analysis, and quality assurance. Through the years, iST has constructed a comprehensive verification and analysis engineering platform, offering full-scope services to the IC engineering industry. iST customers cover the whole spectrum of the electronics industry from IC design to end products. In response to rising environmental awareness, iST not only focuses on its core services but is also expanding its service offerings based on international trends. iST’s lead-free and halogen-free verification testing, chemical quantitative testing and carbon footprint/greenhouse gas inventory services have all been accredited by multiple international independent third-party organizations including TUV NORD Germany and BSI UK. With increased outsourcing by major international brands, iST now also plays the role of independent quality testing laboratory for OBM outsourcing products and is certified by Dell, Cisco, Delphi, Continental Automotive and Lenovo.

Headquartered in Hsinchu, iST’s pursuit of precision, perfection and efficiency has led it to expand its operations around the world. The iST Group now includes iST Kunshan, iST Shanghai, iST Beijing and iST Shenzhen in China, IC Service in Japan, and an iST laboratory in the US. These are all dedicated to providing customers with prompt, reliable and high-quality technical services in order to grow with the leaders of the world. For more information, please visit the iST website at:www.istgroup.com